PUMPS

Diaphragm Pumps

Centrifugal Pumps

Peristaltic Pumps

Progressive Cavity

Flexible Impeller

ATEX Pumps

Gear Pumps

Diesel-Driven Pumps

Magnetic Drive Pumps

Lobe Pumps

Twin Screw Pumps

Submersible Pumps

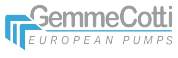

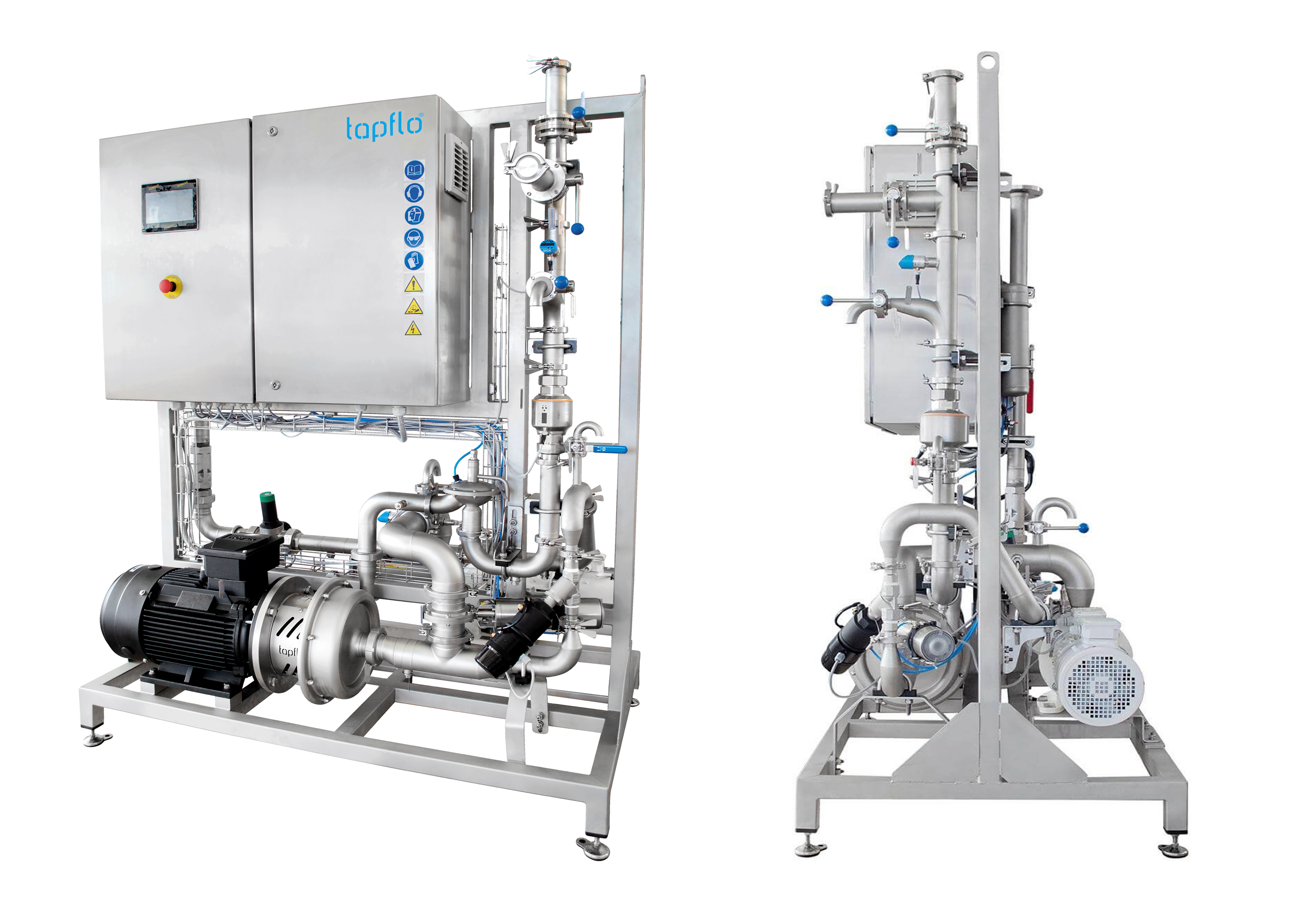

Booster Sets

Drum Pumps

Drum Unloading

SLES System

Mixers

Mobile Solutions

Sanitary Process Valves

Pump Accessories