What is Nitric Acid and what is it used for?

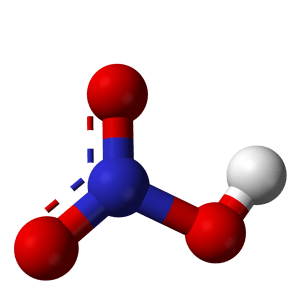

Nitric Acid is a colourless, highly corrosive mineral acid, used in the manufacture of plastics, dyes, fertilisers, and explosives. It is also used as a reagent in scientific laboratories. Nitric Acid is a highly corrosive and strong acid that can cause severe burns. Its chemical formula is HNO3.

What is the most important thing to consider when specifying a pump for Nitric Acid?

Due to the highly corrosive properties of Nitric Acid, the safety of the end-user is paramount when selecting a pump. If a leak should occur and any Nitric Acid should escape the pump, it can cause severe burns and could cause lifelong injuries if it was to come into contact with eyes and skin.

What materials are best suited to Nitric Acid?

Stainless steel is suitable for Nitric Acid up to 70%. We would, however, recommend using a solid block PTFE Pump for anything over 50% to be safe!

What measures can be taken to ensure the end-user is safe and the pump doesn’t leak?

Here at Tapflo, we have a number of products that we can offer to ensure the product is contained. All of our plastic AODD (Air Operated Double Diaphragm) pumps are manufactured from solid block HDPE or PTFE rather than the industry standard, and our diaphragms are bonded from 5 pieces of premium material and have a no-nut clean face! We can also supply barrier protection on all of our Diaphragm Pump range. This means the pump will have an additional set of diaphragms, in the case of a leak the fluid will stay contained in the pump rather than escaping via the air exhaust.

What’s the difference between a solid block and moulded?

Great question! Moulding side housing is generally the industry standard within the diaphragm pump sector. This means that the plastic is melted down and poured into a moulding, this can cause stress to the plastic and can destroy some of its original compounds. All of Tapflo’s Plastic Diaphragm Pumps are machined from either solid block HDPE or PTFE meaning the original compounds are still intact resulting in much higher resistance to harsh substances like chemicals.

Nitric Acid Case Study

Tapflo has been working with a fertiliser manufacturer for a few years now. They recently sent us an enquiry for batching 60% Nitric Acid from an IBC into a depositor that can hold around 50l. They wanted the pump to batch as the depositor was emptying.

Application Details

Fluid: 60% Nitric Acid

Viscosity: N/A

Flow Rate: 10-15lpm

Temperature: Ambient

Solids: None

Pipe Work: 1/2”

Length of discharge: 10m Suction

Condition: 1.2M vertical 2M across

Pumping solution offered

Pump Type: TC50 TTT Low Energy Air Pump

Materials: PTFE

Connection Size: ½”

The pump provided was a TC50 TTT Low Energy Air Pump (LEAP). This was connected to their PLC on where they could set the pump to batch around 12lpm as the depositor was emptying. Due to the pump being from our low energy (LEAP) range they were able to achieve this by using around 1 Bar of air pressure. If they were to use a standard Tapflo AODD over a LEAP they would have had to use around 2.5 Bar.

If you require a similar pump or any assistance on fluid handling within your factory then please get in touch on 02380 252 325 or email us at [email protected]