Want to get the most out of your Centrifugal Pump? This guide can help you achieve the best performance.

Understanding Centrifugal Pump Operation to Achieve Maximum Efficiency

At Tapflo UK we have a large range of Centrifugal Pumps available for a variety of industrial and hygienic applications. Included within our range are our own Tapflo manufactured Centrifugal Pumps and those of our trusted partners so it’s fair to say we know a thing or two about achieving maximum efficiency for your pump and any of our pump technologies. Keep reading to find out more.

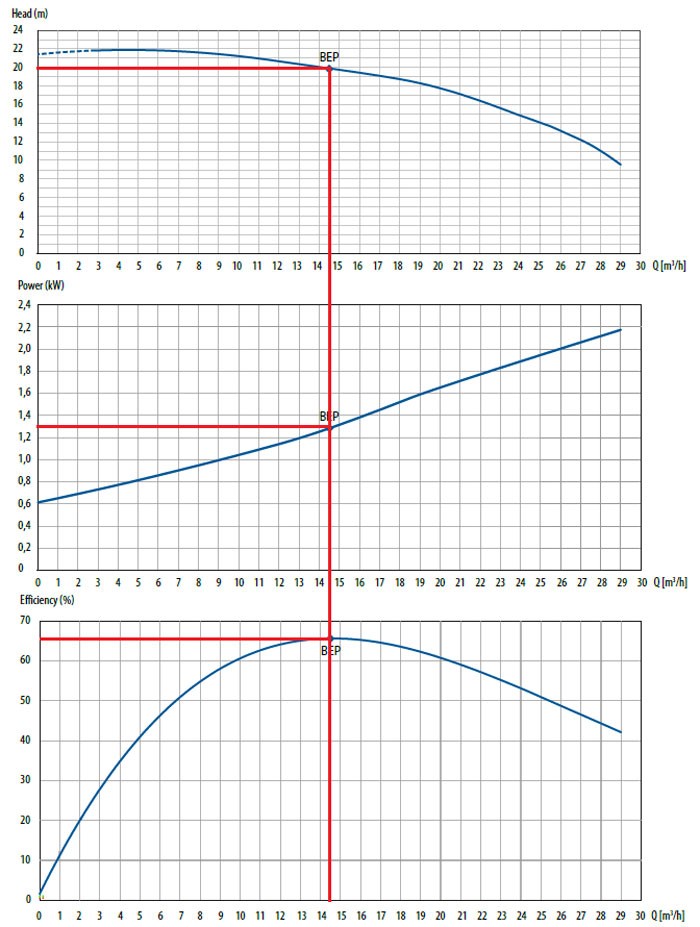

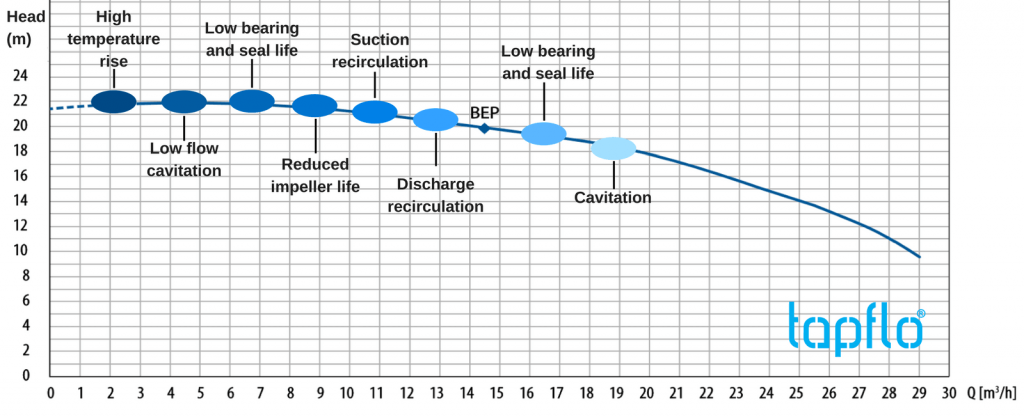

Centrifugal Pump Performance Curves

Ensure your Centrifugal Pump is Operating Efficiently

Cavitation