What are the different pumping options available when pumping mayonnaise?

The simplest way to pump mayonnaise from storage tanks to the process filling line is with an Air Operated Diaphragm Pump. As with all consumables, it is important you use a Sanitary Diaphragm Pump to ensure that your mayonnaise is being transferred through the most hygienic pump possible as the end-use will be consumed. Our Sanitary Diaphragm Pump is FDA approved and manufactured from a superior grade metal, AISI 316L Stainless Steel. You can find out more about Sanitary Diaphragm Pumps in our article ‘They can do that? 5 Secrets about Sanitary Diaphragm Pumps!’

A Diaphragm Pump creates a suction lift of up to 0.4 metres dry and 0.9 metres wetted, making them simple and flexible to install. As long as the mayonnaise is under sixty thousand centipoise, then a Diaphragm Pump will prime from a low height with the only limitation being reduced open-end flow. Another important benefit of these pumps over other pump options is the simplicity of control offered by the pneumatic power. We can also fit your Diaphragm Pump with a range of control accessories such as batching control and level control. Using an AOD couldn’t be more straight forward!

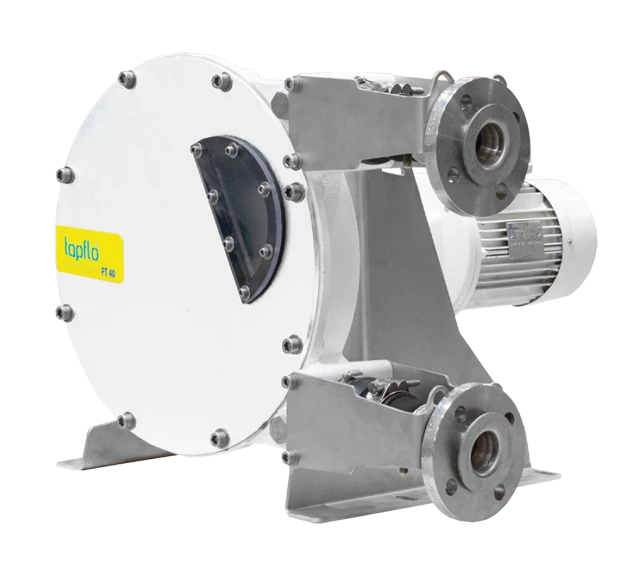

Sanitary Lobe Pump

Sanitary Lobe Pumps are possibly the most common choice of pumping technology for mayonnaise because they’re widely trusted as the market leader for food-grade processing pumps. Lobe Pumps have a key benefit over other choices in the sense that you get an entirely pulse-free flow whilst also ensuring the integrity of the product is not damaged. Due to the pump having a positive displacement, it offers a gentle pulse-free flow. The only drawback of a Lobe Pump is that they require flooded suction, which means they can’t be run dry as this will cause damage to the mechanical seal.

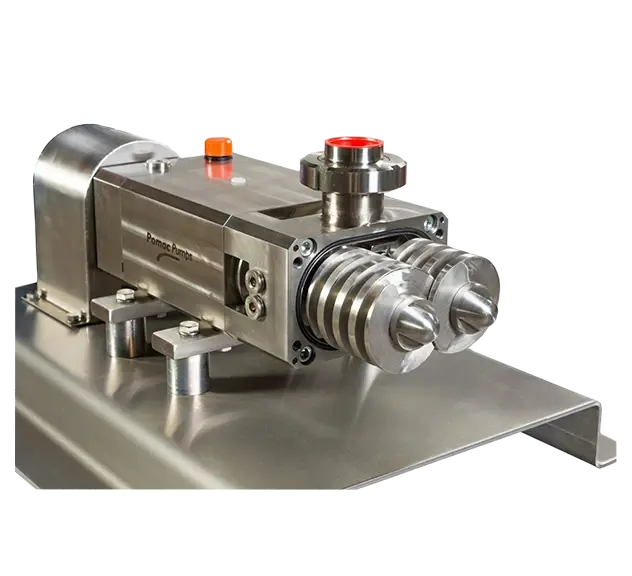

Sanitary Twin Screw Pump

Possibly the most popular style of food processing pump of 2018, Sanitary Self Priming Twin Screw Pumps are quickly becoming the market leader for the transfer of viscous food products. Screw Pumps have a very interesting feature where they can be used either for process or for Clean In Place (CIP) duties by ramping up the RPM, thus giving you two pumps for the price of one!

Screw Pumps also create great suction once wetted by pulling a vacuum in the pump’s suction line. Similarly to Lobe Pumps, a Twin Screw Pump offers pulse-free flow and the possibility to self-prime. Click here to read Benefits of using a Twin Screw Pump

Peristaltic Pump

Want to know more? Read our article on the Benefits of using a Peristaltic Pump. A Peristaltic Pump can create the best suction of any pumping technology available on the market, pulling an impressive 0.95 meters dry or wetted. This is a huge benefit when pumping thick products such as mayonnaise, as it allows you to install the pump in either a flooded suction setup or a pulling out of the drum setup. An added benefit of using a Peristaltic Pump is its ability to run dry without any adverse effects on the pump, this is something only a Peristaltic Pump and a Diaphragm Pump can do, however, it is important to remember that you cannot leave them dry running indefinitely as this will cause serious wear to the pumps.

What is the best practice for setting up my pump to move mayonnaise?

When setting up your pump, it’s important to consider the pros and cons of each pump type as detailed above. Whichever pump you decide to use, providing it with flooded suction will always help the process performance to the best of its ability. It’s also important to ensure you install the pumps with the relevant valves and fittings to enable easy and safe maintenance. We’re more than happy to help you with this in our quote, just get in contact with us at [email protected]

To summarise, how do I decide which pumping technology is best suited to my application?

Picking the pump best suited to your application is vital to ensuring minimal downtime and maximum life of the pump. The key considerations are:

- Does the unit need to prime to the product or can I put the pump under the storage tank?

- Do I require a smooth gentle flow, or can I leave with a pulsating flow?

- What source of power do I have, air or electric?

- What installation will the pump be fitted into?

The pumps highlighted above are the ideal options for pumping mayonnaise because they can handle a thicker product and are all sanitary pumps, perfect for pumping consumables.

Case study:

Tapflo were approached by a customer looking for three pumps to move mayonnaise from a large bulk storage tank to the process filling line.

Duty: 187 LPM

Head pressure: 2.5 bar

Suction: Flooded

Power requirements: 3 Phase electrical supply

Solids: No

Tapflo provided three PLP Lobe Pumps to the customer in June 2018, which are now set up sat at the bottom of the IBC and controlled by the factory’s PLC system. The system opens and closes valves as turning the pump on and off. The customer was very happy with the pumps provided and has had no issues since!

If you have any more questions about pumping mayonnaise or you’re having a problem with your current pump, get in touch with the Tapflo team today where we’d be happy to advise on the best solution for you.

T: 023 8025 2325

Alternatively, you can open the live chat in the bottom right-hand corner of your screen to talk to someone in the office now!