We all love a bit of custard on our pudding, don’t we?! Here at Tapflo, we can pump a variety of products, with delicious custard being one of them! If you’re pumping custard or something of a similar thickness, the FAQ’s and case study below could help you with any questions you may have. If your question isn’t listed below, give us a call or drop us an email and we’ll be more than happy to help!

What Pumps can be used for Transferring Custard?

Tapflo UK is capable of supplying the following pumps for use with Custard transfer:

What are the Difficulties when Pumping Custard?

There are a number of factors which need to be taken into account when pumping Custard, such as:

- Custard is classed as a shear thickening or dilatant fluid which means that the more it is mixed or sheared, the thicker the fluid gets.

- As corn syrup is used in the production of custard, the more force imparted onto it, the harder it gets.

- The presence of suspended sugar particles within the custard means that it can be abrasive to rotating elements within the fluid, as well as the seal faces.

- At standstill and at room temperature the product can be particularly vicious, so it needs to be gently mixed and heated continuously to maintain an ideal viscosity.

Why Can’t I use a Centrifugal Pump for Pumping Custard?

Centrifugal Pumps are generally only recommended for low-pressure transfer applications of Newtonian fluids, such as water & milk, with a maximum viscosity of up to 500 cPs (1000 rpm max). As the viscosity of custard is generally higher than 4000 cPs, the pump is likely to be starved on the suction side and bore a hole in the centre of the fluid in the suction tank as it is running too fast. The fluid that reaches the pump and is discharged will most likely be thickened by the high-speed action of the impeller, resulting in the pump effectively-being dead-headed due to overpressure.

This will subsequently result in the pump experiencing cavitation and the motor tripping out due to drawing too much current. In this instance, we would generally recommend using a Hygienic Lobe, Twin Screw or Peristaltic Pump which can operate at speeds lower than 500 rpm. This will enable smooth drawing of the fluid into the pump and gentle and slow conveyance of the fluid into the discharge pipework. It will also avoid thickening the fluid due to over agitation.

What Type of Sealing Would you Recommend when Pumping Custard?

As custards generally contain suspended and dissolved sugar particulates, they can be abrasive and also sticky when left to dry. As a result, we would generally recommend a quenched or flushed mechanical seal, back-to-back, with at least a 2 bar overpressure to ensure that the seal faces are constantly cleaned during operation. Should the primary seal fail, the product is kept inside the pump head rather than leaking out of the back of the seal housing. Alternatively, we can also supply our Air-Operated Diaphragm Pumps or Hygienic Peristaltic Pumps, which are sealless and avoid all issues associated with Mechanically Sealed Pumps or ones fitted with Packed Glands.

Custard Pump Case Study

Tapflo were recently approached by food production customer with a custard production application, which required a pump for transferring custard to their mixing and heating vessel onto the hopper system for delivery of the product. They had tried a couple of different pumps to date with varying results and inconsistent reliability due to seal failures and inconsistent flow rates. Tapflo UK was more than happy to help!

Application details:

- Fluid: Confectioners Custard

- Temperature: 35ºC – Temperature to be maintained

- Viscosity: 4000 cPs

- S.G: 1.1 kg/dm³

- Required Capacity: up to 3 m³/hr @ up to 5 Bar

- Suction Conditions: Flooded from bottom outlet of mixing and heating vessel

- Required Connection Type: 2” RJT Pipework Size: 2”

- Motor Supply: 230-400V/3 Ph/50 Hz

Pump supplied:

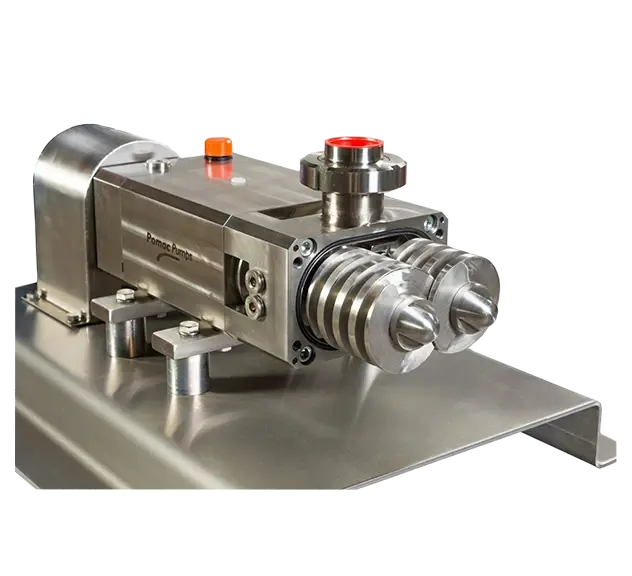

- Model: PLP 2-2

- Description: Long Coupled, Hygienic Lobe Pump with Bi-Wing Rotors & Heating Jacket

- Rated Capacity: 3 m³/hr @ up to 5 Bar (176 rpm)

- 2” RJT w/Weldable Counter Connections

- SS 316L Wetted Components w/Hardened Rotors, Electro-polished to 0.8 Micron

- SS 304 Gearbox

- Back-to-Back Mechanical Seal w/ EPDM Elastomers (FDA Approved)

- Geared Motor 1.5 kW/4 Pole/230V/3 Ph/50-60 Hz/IP55/Class F/IE3 Premium Efficiency Class

The pump was delivered within 5-6 working weeks with FOC dummy rotors and a removal tool, for easy removal of the lobes for mechanical seal changes and CIP (Clean In Place). The customer has put the pump on the line and has had no problems with performance or breakdowns since!

If you require a similar pump or any assistance on fluid handling within your factory, then please get in touch.