A CIP Pump is essential for businesses looking to keep their application as sanitary as possible. Many pump suppliers, including Tapflo, use the term CIP as an abbreviation. Find out below what this means for your Pump and the options available.

What is CIP?

CIP is the abbreviation for “Clean In Place”, which means the cleaning in place of the vessels, equipment and pipework that come in contact with the product, without dismantling. This involves the pre-rinse, cleaning, final rinse and sterilisation of a hygienic process, which can be done at temperatures up to 85ºC and involves either acid or caustic detergents with numerous sanitisers. CIP Systems can be either “Single-Use”, where the CIP fluid is wasted at the end of each use, or “Recovery” based where the fluid is recycled for re-use for further cycles.

What is a CIP Pump?

A CIP Pump is required to be hygienic and in compliance with FDA regulations and typically EHEDG certified, in order to ensure the CIP process is as sanitary as possible. Centrifugal Pumps are typically used as they are ideally suited to supply fairly large volumes of water like fluids at reasonable pressures, up to approx. 16 Bar.

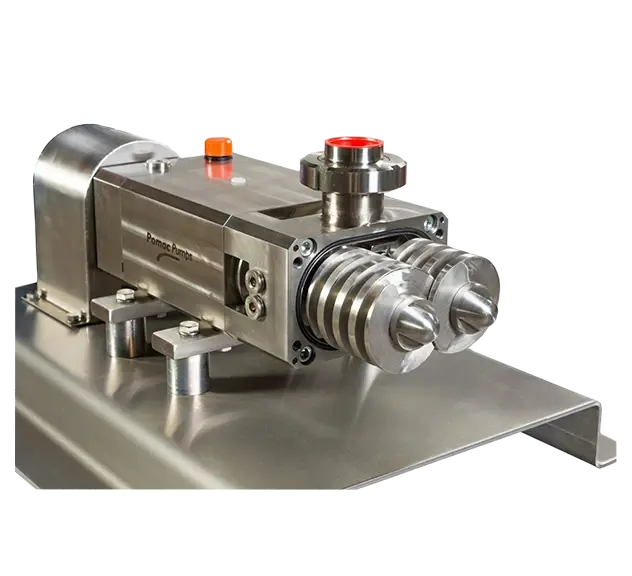

Furthermore, most hygienic pumps in contact with the product are typically positive displacement pumps that are not suited to pumping water or at the capacities required for a CIP process. However, we can also supply our PDSP Hygienic Twin Screw Pumps to pump both the product and the CIP fluid in both supplies & scavenge applications, simplifying the process and negating the need for extra pumps in the process.

When to use a CIP Pump

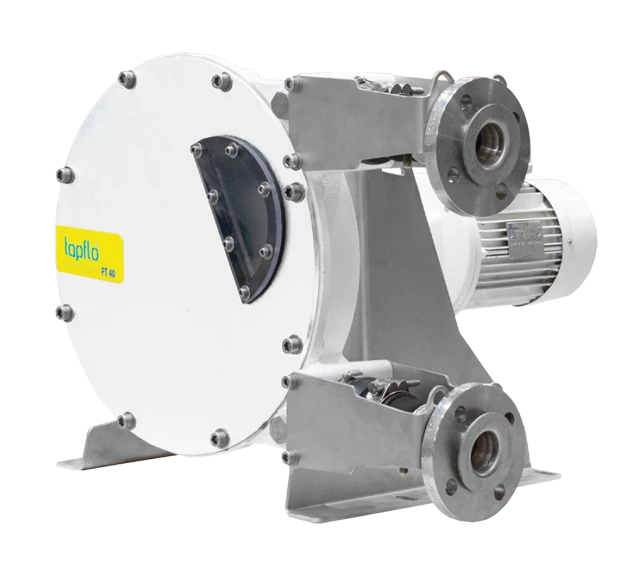

CIP systems feature at least 2 types of pumps in 2 different positions. The first is the CIP Supply Pump, generally a Hygienic End Suction Centrifugal Pump, which pushes the CIP fluid round the process.

The CIP Supply Pump typically does 2 feeds a spray system in a process vessel with large volumes of the CIP fluid at fairly high pressures, depending on the type of spray heads used (Static Spray Balls, Rotating Spray Heads or Cleaning Machines). The second is the CIP Scavenge and/or Return Pump which evacuates the CIP fluid from the process vessel and pipework and either pump it to waste or returns it for recycling and re-use. These are generally Hygienic Self Priming Centrifugal Pumps (see CPC-ZA or CTS-H pumps) or Hygienic Liquid Ring Pumps (see SP-LR Pumps).

How do I Quantify my CIP Flow Rate Requirement?

The flow requirement for CIP is determined by the minimum velocity required through the size of pipework in place. This is typically 1.5 m/s minimum. As such your CIP flow requirements can be quantified as follows:

| Process Pipe ø, mm | CIP Supply Return Pipe ø, mm | Minimum CIP Flow, m³/hr |

| 25 | 25 | 2.1 |

| 38 | 38 | 5.2 |

| 50 | 50 | 10 |

| 65 | 65 | 16 |

| 75 | 65 | 24 |

| 100 | 75 | 42 |

| 125 | 100 | 70 |

| 150 | 125 | 100 |

| 200 | 150 | 170 |

| 250 | 200 | 280 |

| 300 | 200 | 400 |

| 350 | 250 | 520 |

| 400 | 250 | 700 |

Tapflo CIP Pump Case Study

Tapflo Pumps UK was recently contacted for the supply of a hygienic pump for use on both liquid stock and CIP, as they wanted to simplify their CIP pipework and limit the number of pumps they have on-site, therefore limiting spares holding and maintenance times & procedures. We at Tapflo UK were only too happy to help!

Application Details

- Fluid: Liquid Stock

- Temperature: 70-110ºC

- Viscosity: 1-2000 cPs

- S.G: 1.1 kg/dm³

- Required Capacity: 30 m³/hr @ 2 Bar (Liquid Stock) & 50 m³/hr @ 2 Bar (CIP)

- Suction Conditions: 200 mBar vacuum on evaporator tank (Liquid Stock Duty)

- Required Connection Type: DN100 / 80 Tri-Clamp

- Pipework Size: Sized to suit pump

- Motor Supply: 230-400V or 400-690V / 3 Ph / 50 Hz

Pump Supplied

- Model: PDSP 3-60

- Description: Long Coupled, Hygienic Self Priming Screw Pump (Double Screw)

- Rated Capacity: 30 m³/hr @ 2 Bar (40 Hz) & 50 m³/hr @ 2 Bar (70 Hz)

- DN100/DN80 Tri-Clamp Counter Connections w/ Weldable Counter Parts

- SS 316L Wetted Components, 0.8 Ra Surface Finish w/ Hardened Screws

- SS 304 Gearbox

- Single Mechanical Seal, SiC/SiC/EPDM Elastomers (FDA Approved)

- Motor 15 kW/4 Pole/400-690V/3 Ph/50-60 Hz/IP55/Class F/IE3 Premium Efficiency Class

The pump was delivered within 6-8 working weeks and the customer was over the moon with the performance on both process and for CIP pumping.

If you require a similar pump or any assistance on fluid handling within your factory then please get in touch on 02380 252 325.