Our range of Pump Accessories & Parts are used to optimise performance. From Pulsation Dampeners and Valves to Flow Meters and Frequency Inverters for precise control, these components ensure seamless integration & enhanced efficiency across Industrial & Hygienic applications, extending equipment lifespan.

Diaphragm Pump Guardian System

Diaphragm Pump Pneumatic Batch Controller

Diaphragm Pump Pneumatic Level Controllers

Diaphragm Pump Pressure Switch

Diaphragm Pump Life Counter

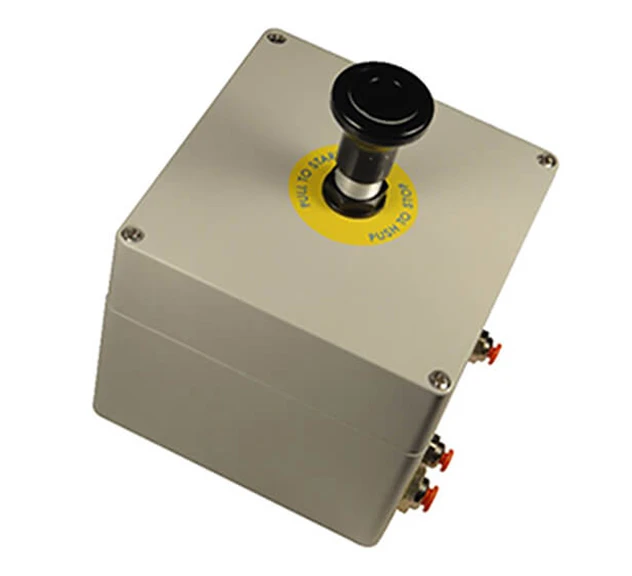

Pneumatic Start Stop Units

Electronic Batch Controller

Wall Mount Decanting Units

Heating Jacket

Automatic Barrel Filling Kit

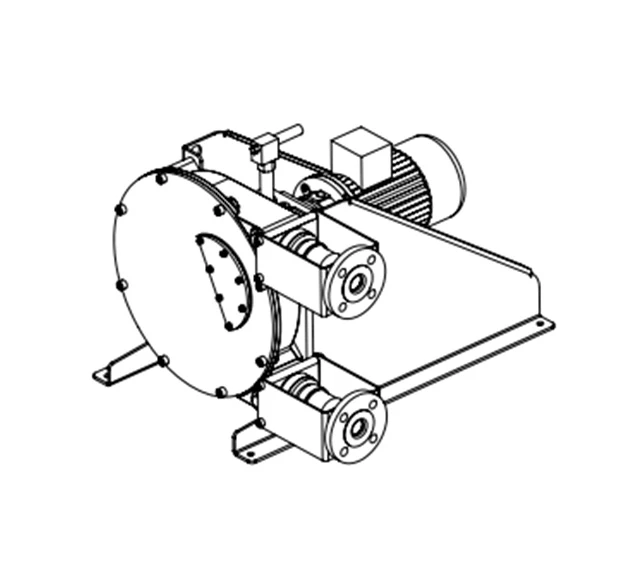

Industrial Grinder

Flexible Impeller Pump Accessories

Metal Diaphragm Pump CAM Lock Connections

Sanitary Series Counter Connections

Electronic Dual Action Pressure Switch

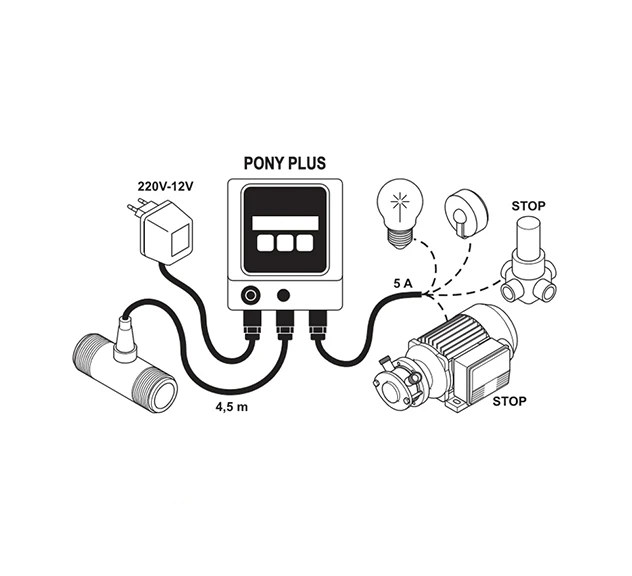

Pony Plus Batch Controller

Flow Meters

Vacuum Assist System

Frequency Inverters

NORD SK180 Motor Mounted Variable Speed Drives

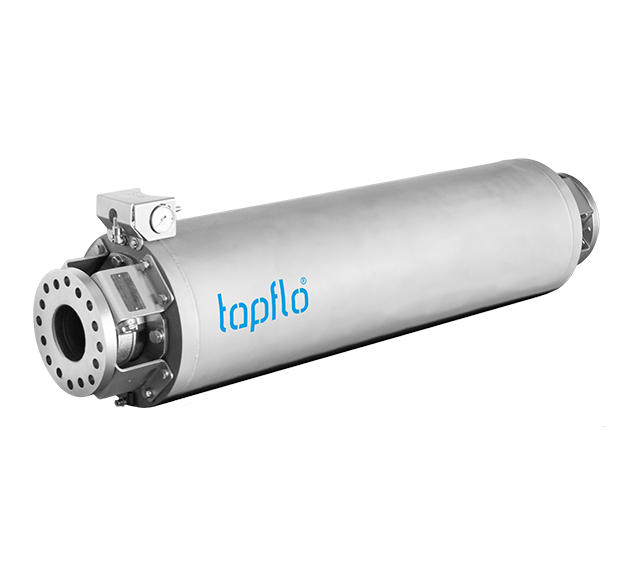

Peristaltic Pump Pulsation Dampener

Insulating Covers for Diaphragm Pumps

Valves

Hygienic & Industrial Trolleys

Hose Assemblies & Fittings

Pulsation Dampeners for Diaphragm Pumps