Our Magnetic Drive Pumps, available as Vane, Centrifugal, or Turbine Mag Drive Pumps, offer superior corrosion resistance for Industrial & Hygienic sectors, boasting a sealless design, with flanges available on request, and an innovative impeller magnet assembly. For enhanced safety, these pumps offer dry-run protection & are ATEX-available.

Mag Drive Centrifugal Pump

Plastic Regenerative Turbine Pump

Plastic Magnetic Drive Centrifugal Pump

Plastic Volumetric Vane Pump

Moulded Plastic Centrifugal Pump

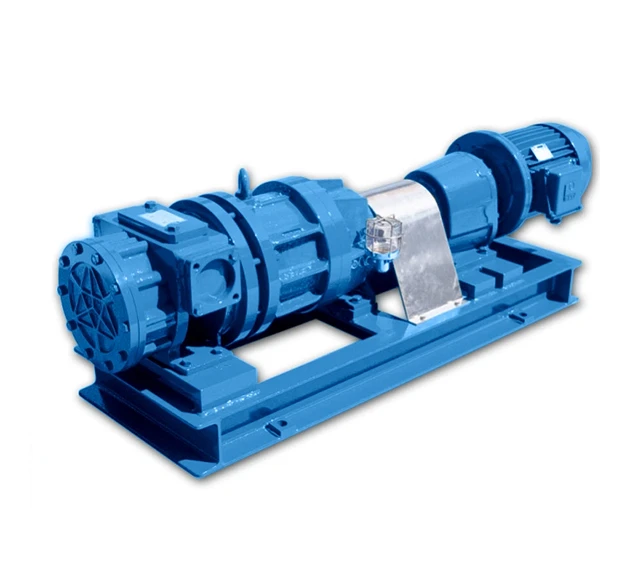

Two Stage Regenerative Turbine Pump

Oscillating Piston Pump

Alloy Regenerative Turbine Pump

Magnetic Drive Stainless Steel Centrifugal Pump

Magnetic Drive Hot Oil Gear Pump

Metal Magnetic Drive Centrifugal Pump

Metal Volumetric Vane Pump

Magnetically Driven IBC Portable Pump Unit

Filtration & Purification System

Magentically Driven Vane Pump

Magnetically Driven Turbine Pump

Magnetically Driven Centrifugal Pumps