Our high-performance Flexible Impeller Pumps are manufactured by Italian manufacturer Liverani.

Using high-quality rubber impellers & housed vanes, they effortlessly handle thin, viscous & shear-sensitive fluids and solids in suspension, ensuring suitability for emptying sumps, tanks, drums & IBCs. They consist of a simple construction & few moving parts for a pulsation-free flow.

All-In-One Flexible Impeller Pump

Bare Shaft & Hydraulically Driven Flexible Impeller Pump

EP Flexible Impeller Pump

Gearbox Drive Flexible Impeller Pump

Inverter Drive Flexible Impeller Pump

Miniverter Flexible Impeller Pump

V-Belt Drive Flexible Impeller Pump

VA & INV Flexible Impeller Pumps

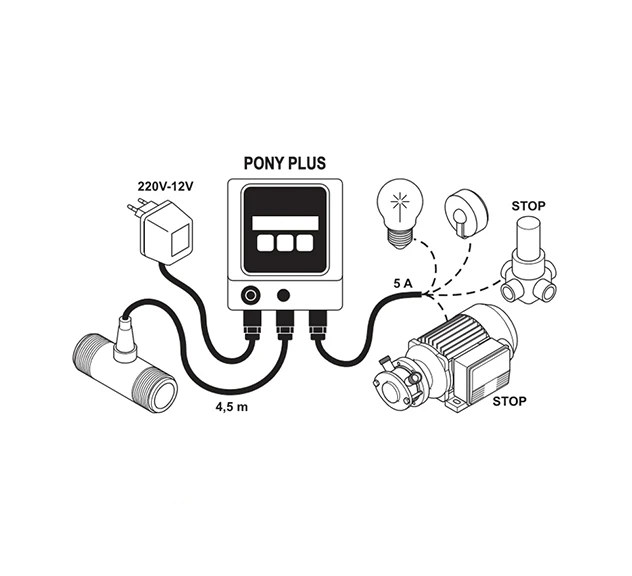

Pony Plus Batch Controller

Flexible Impeller Pump Accessories