A leading global Food Manufacturer was looking for a more efficient and reliable solution for managing wastewater from its production process. The company previously relied on a sump system, which faced repeated issues, including unreliable pump performance, frequent blockages, and overflow incidents that caused costly downtime and operational inefficiencies.

As a company committed to sustainability, our client also required a solution that aligned with its environmental standards and corporate social responsibility goals. We provided a custom-engineered Effluent Management System designed to meet these needs, ensuring both performance and sustainability improvements across the board.

Application Details - The Challenge

Our client’s existing sump system had a 5,000-litre capacity, designed to handle wastewater from 7 different waste streams. However, this sump frequently overflowed due to ineffective control elements and pumps that struggled to keep up with the effluent flow. In addition to flow and overflow issues, the sump suffered from blockages caused by large debris, such as cable ties and labels that entered the system, causing operational delays.

Given these challenges, our client was looking for a scalable effluent system to replace the sump, manage larger volumes of wastewater, and prevent blockages, ultimately improving efficiency and reducing maintenance demands.

Components of the System - The Solution

To address these needs, our Engineering Department designed and installed a 10,000-litre custom tank with a 110% bund for spill containment. A duplex automated basket filter system was added to catch large debris, ensuring smooth operation and reducing the risk of blockages. When one filter basket becomes blocked, the system automatically switches to the other, allowing for uninterrupted flow and the ability to clean the blocked basket, which reduces maintenance downtime. A custom locking mechanism stops operators from opening the basket in use. An alarm then sounds, alerting operators that cleaning is required, ensuring proactive maintenance and minimising downtime.

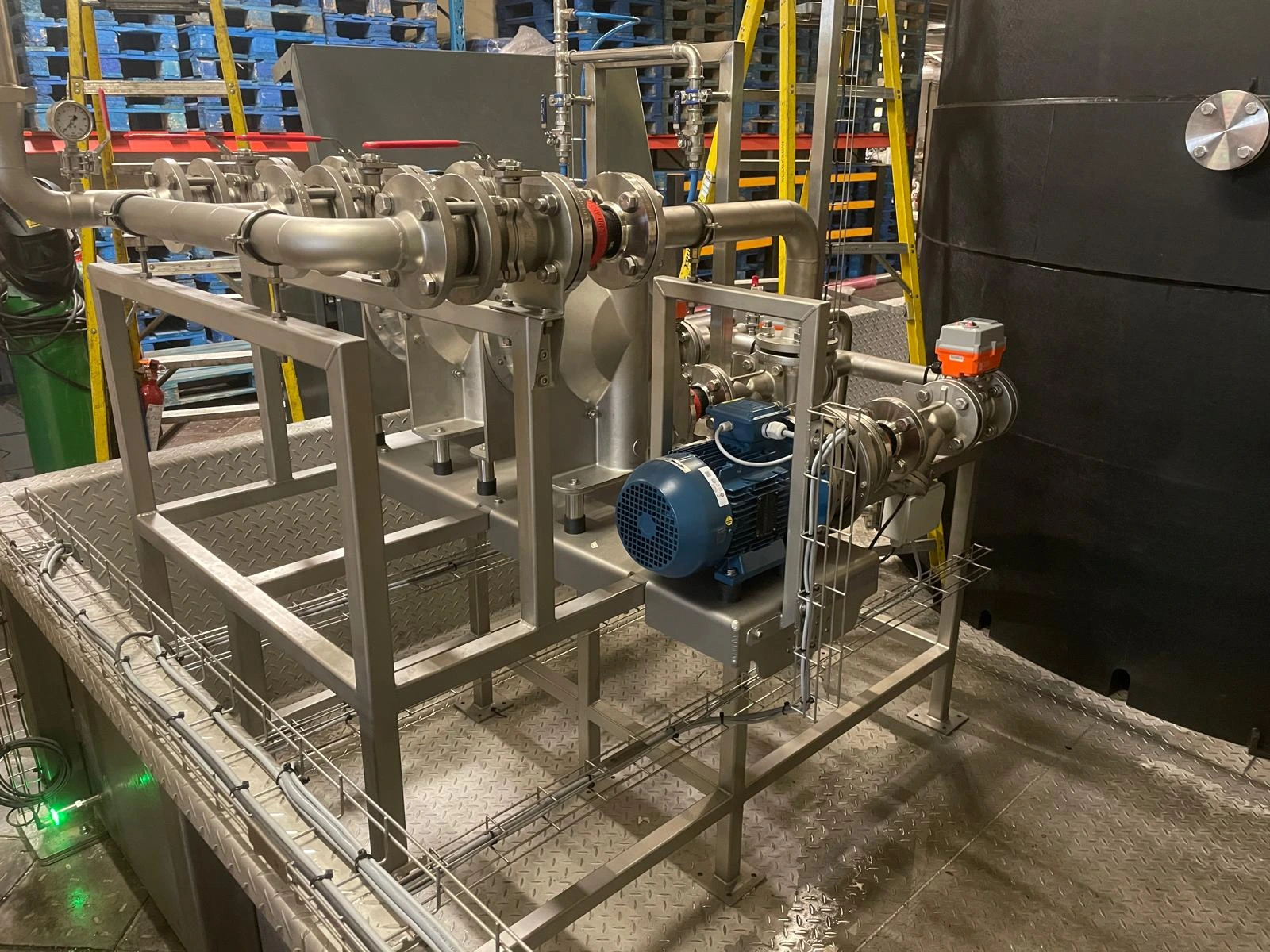

New Pumping System

The custom effluent system was equipped with a combination of LEAP (Low Energy Air Pump) technology and a high-performance CTX-I centrifugal pump, delivering both sustainability and high operational efficiency.

- LEAP Technology for Sustainability: 2x TC420 LEAP Diaphragm Pumps were fitted, which reduces operating air pressure to as low as 0.2 Bar, achieving up to 70% in energy savings compared to traditional Diaphragm Pumps. LEAP’s lower starting pressure and reduced pulsation align with the client’s sustainability initiatives and significantly cut operational energy costs. Additionally, the LEAP pumps include features such as ultra-low starting pressure, easy maintenance, noise reduction, and simplified control that supports efficient and quiet operations ideal for a production setting

- CTX-I High-Performance Centrifugal Pump for Robust Performance: The CTX-I Pump, known for its reliable, high-efficiency performance, was chosen to further enhance the system’s robustness and minimise downtime. The CTX-I’s modular design allows it to handle a variety of installation conditions with minimal maintenance, which is essential in managing the confectionery facility’s complex effluent streams. This pump features low NPSHr, low noise levels, and adjustable impellers, ensuring optimal performance with flexibility for future adjustments if required. Its design accommodates solids in suspension, a key advantage for effluent handling. Furthermore, the CTX-I’s construction and double mechanical seal option add to its durability, making it a reliable choice for industrial applications

The system also included:

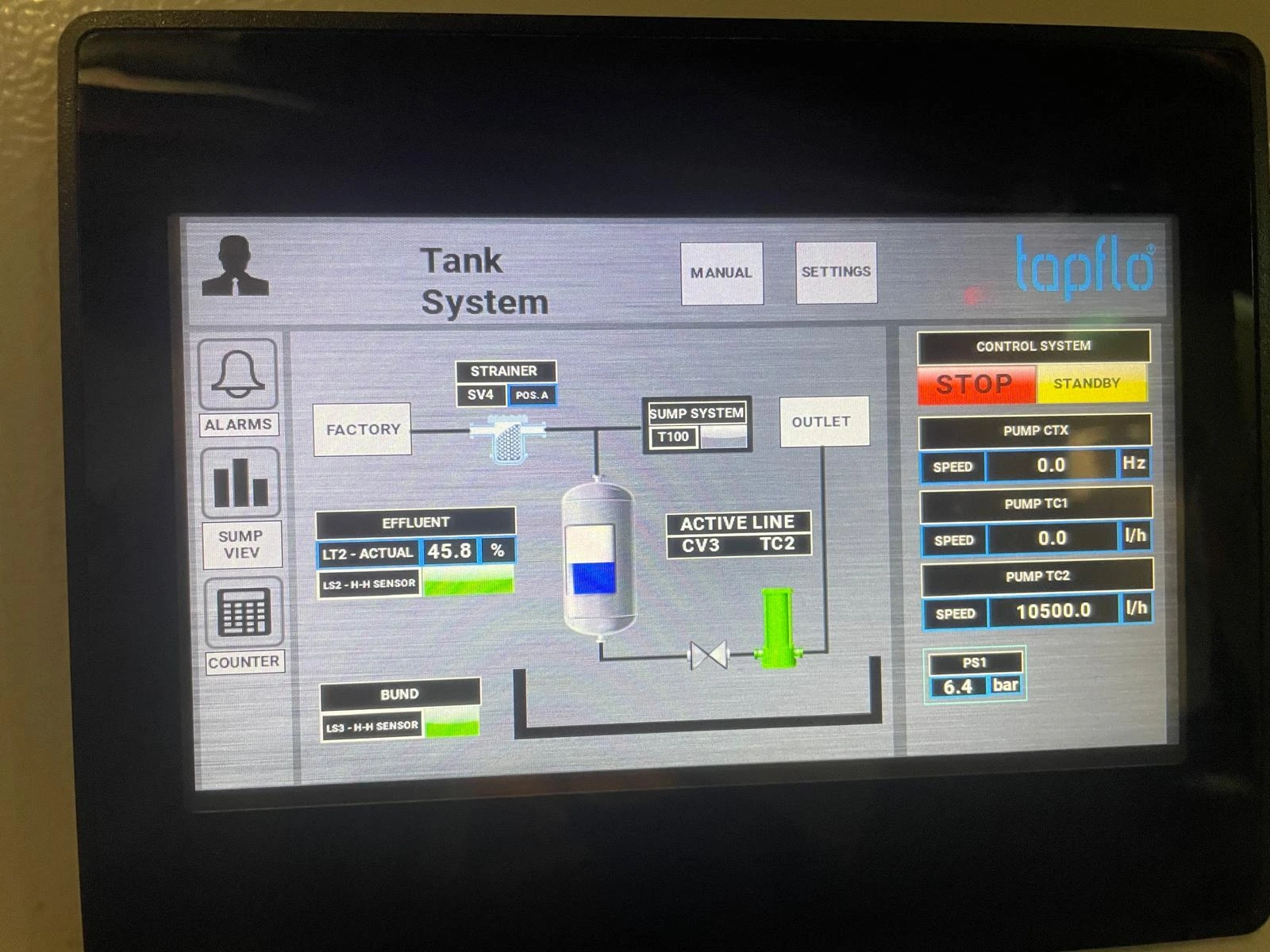

- 10,000L Tank with VEGA Radar Sensors: High-level radar sensors provide continuous monitoring, and a separate high/high level switch acts as a secondary alarm to prevent overflows

- Pump Arrangement: To ensure reliable operation, pumps were arranged in a duty/standby/standby configuration with an unbalanced cyclical changeover to even out wear. This configuration ensures system readiness and prevents pump seizure whilst ensuring that the pumps run for differing amounts of time

- Electric Actuated Ball Valves: Electric actuated ball valves enable precise control over pump usage and flow supply isolation, making it easier for operators to manage effluent streams

- Pressure Monitoring: A common suction and discharge manifold was fitted with a pressure gauge to monitor discharge levels, providing real-time operational insights

- Mechanical & Electrical Installation: We integrated 6 of the 7 effluent streams into a single system for streamlined waste management

Benefits of the Solution

The custom effluent management system delivered significant benefits, addressing our client’s requirements for improved efficiency, reliability, and sustainability. Key advantages included:

- Increased Capacity: By doubling the tank capacity from 5,000 to 10,000 litres, the system accommodated higher waste volumes, reducing the risk of overflows.

- Reduced Blockages: The automated duplex basket filter system captured large debris, preventing pump clogging and minimising operational disruptions.

- Energy Savings and Sustainability: Our LEAP technology significantly reduced our client’s energy consumption, supporting their sustainability goals and lowering operational costs.

- Enhanced Reliability and Maintenance Ease: The duty/standby/standby pump arrangement, combined with automated alerts and easy-access filters, optimised system performance, allowing for routine maintenance without affecting operations.

- Control and Monitoring: The installation of VEGA radar sensors, electrically actuated valves, and pressure gauges provided real-time data, giving operators full control over the effluent system and enhancing predictive maintenance capabilities.

With these features, our client achieved a more sustainable, efficient, and reliable effluent management system that worked within the wastewater treatment system, whilst aligning with its corporate commitment to environmental responsibility while reducing operational costs and downtime.

Get in touch with our team today for tailored application support and to learn more about what our Engineering Department can offer for your application!