Tapflo UK is a leading manufacturer of process pumps with a global reputation for providing reliable, efficient and cost-effective pumping solutions for a wide range of industries. Recently, one of our clients operating in the Marine Industry approached us looking for a system that could supply air compressors with a constant fuel source. To meet this challenge, Tapflo UK’s in-house design and engineering team designed and built a robust diesel pumping and filtering system perfectly tailored to their requirements.

Application Details

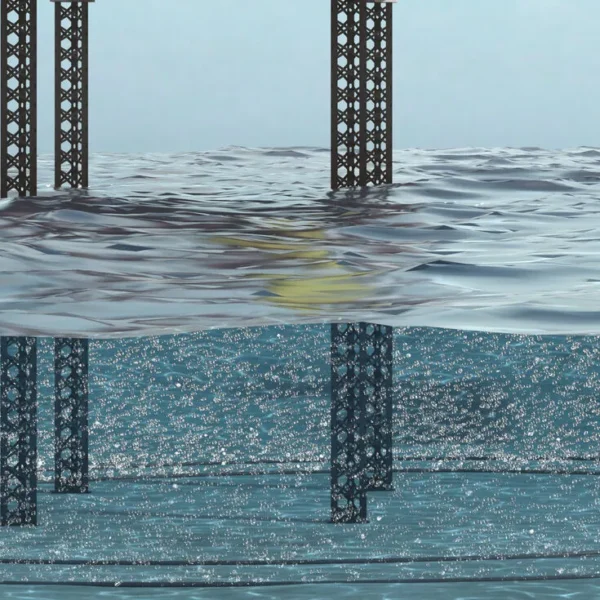

This system was built to supply 12 air compressors with a constant fuel source. The compressors are used to supply the compressed air needed for bubble curtains used during off-shore drilling operations.

Bubble curtains are predominantly used to:

- Reduce transmission of shock waves (acoustic waves from engines or pile driving, explosions etc.)

- Reduce liquid or debris floating on the surface from spreading

- Prevent salt intrusion

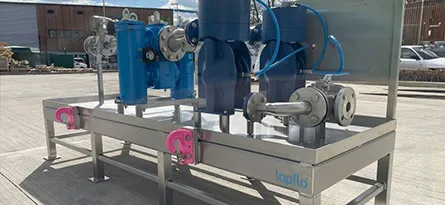

Components of the System

- 2x Tapflo Diaphragm Pumps with built-on Pulsation Dampeners. The pumps are PTFE coated and are capable of pumping diesel at a rate of 3.5m³/hr

- 1x Pressure Relief valve & 1x Battery-Powered Flow Meter

- 1x Duplex Manual Changeover Filter with 10-micron filter baskets

- Stainless Steel 316 frame

- Stainless Steel 316 pipework

- Filter Regulator Kit

- Pressure & Temperature Gauges

- Pneumatic Actuated Shut-Off Valve

- 4x Lifting points

Solutions & Benefits

- Diaphragm Pumps were used as they allow for high flow rates and compact design without the requirement for power, as they are a pneumatic pump whose compressed air can be drawn from the compressors it’s supplying.

- The pumps have a custom PTFE coating to provide increased protection from the harsh salty atmosphere experienced on off-shore vessels. The built-on Pulsation Dampeners provide active dampening to the discharge fluid, ensuring a constant and steady flow of fuel to the compressors.

- The duty/standby configuration of this system allows for the pumps to share runtime, therefore extending the periods between maintenance. This configuration also allows for 1 pump to be maintained whilst the system is still running.

- The system has a duplex filter which has 10-micron filter baskets that ensure no debris from the fuel tanks gets into the compressors. The filters have a manual changeover function that allows for 1 pump to be cleaned while the other is in operation. This provides seamless operation and minimal downtime. The filter is also fitted with differential pressure indicators which clearly indicate the condition of the baskets and when they need cleaning.

- The pressure relief valve has been fitted to ensure there is minimal (1Bar) pressure built up inside the discharge pipework.

- As the client requested a flow meter (and considering there’s no power available), we opted for a long-life battery-operated device. This ensures continued operation throughout its life cycle.

- This system includes 3-way valves on its pump suction discharge and air supply. This provides a failsafe way of only having 1 pump in operation at a given time.

- The systems’ frame and pipework are constructed from Stainless Steel 316 to provide the best resistance to the off-shore environment.

Tapflo UK’s Custom Duty Standby Diesel Pumping & Filtering System provides a reliable and efficient solution for supplying compressed air for bubble curtains used during off-shore drilling operations. The system’s robust design and components ensure continuous and uninterrupted fuel supply to the compressors, ensuring the bubble curtains operate effectively.

The system’s features, including Diaphragm Pumps with built-on Pulsation Dampeners, Pressure Relief Valve, Duplex Manual Changeover filter, battery powered Flow Meter and stainless steel pipework ensures that the system is safe, efficient and reliable.

The system is a testament to Tapflo UK’s commitment to providing innovative and cost-effective solutions to its clients.