In the Paint, Print and Varnish industry, the seamless transfer of a diverse range of fluids is not just necessary, it’s crucial to operational success. Now when it comes to pumping paint, this is a task that requires precision and reliability. At Tapflo UK, we take pride in offering a comprehensive range of Paint Pumps meticulously designed to enhance your operational processes.

In this Guide to Pumping Paint, we’ll uncover the intricacies of pumping paint, highlighting the unique challenges posed by fluids such as water-based paints, inks varnishes and pigments, and looking at the range of pumps we supply for this industry.

What to Consider When Pumping Paint

- Paint Type: identify whether you are pumping water-based paints, solvent-based paints, inks, varnishes, pigments, acrylics or other specialised formulations

- Viscosity: understand the viscosity of the paint as it influences the choice of pump and pumping mechanism

- Chemical Compatibility: ensure that the materials used in the pump are chemically compatible with the paint to prevent corrosion or damage

- Abrasiveness: consider the abrasiveness of the paint as this can affect the pump’s components over time

- Temperature Sensitivity: check if the paint is sensitive to temperature changes and choose a pump that can handle the required temperature range

- Solid Content: determine the level of solids or pigments in the paint as this can impact the pump’s ability to handle the fluid

- Shear Sensitivity: some paints may be sensitive to shear forces so select a pump that minimises shear to maintain the paint’s integrity

Overview of Paint Pumps in Our Range

Peristaltic Pumps:

PT High-Pressure Peristaltic Pump

Peristaltic Pumps are a smart choice for many applications as they limit contact between the pump and the substance being pumped. These pumps use a shoe or roller to press against a rubber hose, similar to squeezing toothpaste from a tube. Ony the hose comes into contact with the fluid being pumped, allowing these pumps to handle highly acidic substances without causing damage. The hose is manufactured from reinforced rubber with specific hoses designed for paint transfer available. Our PT High-Pressure Peristaltic Pump is ideal for the following paint pumping applications:

- Paint

- Water-based paint

- Acrylics

- Pigments

- Wall paints

What are the benefits of using the PT High-Pressure Peristaltic Pump for pumping paint?

- Pulsating flow provides consistency and accuracy

- Dry run – for tank emptying

- Dosing capabilities and pigment transfer

Diaphragm Pumps:

Our Diaphragm Pumps are air-operated, driving diaphragms inside the pump housing. The diaphragms work simultaneously to draw a set volume of liquid into one side of the pump, whilst the other diaphragm pushes out the same volume of liquid. We have three Diaphragm Pump options that are perfect for pumping Paint:

- PTFE Coated Diaphragm Pump

- HDPE & PTFE AODD Pump

- Powder Pump

PTFE Coated Diaphragm Pump:

PTFE-coated Diaphragm Pump

The PTFE-coated AODD was developed specifically for the printing industry to handle the transferring of slightly acidic or alkaline liquids. The pump’s aluminium body isn’t chemically resistant and so it has been coated with PTFE to handle applications in the printing industry such as ink, paint, latex, resins and pigments.

HDPE/PTFE Diaphragm Pump:

HDPE/PTFE Diaphragm Pump

The HDPE & PTFE AODD applies the ingenious Tapflo design of solid block HDPE or PTFE for a Diaphragm Pump with extremely high corrosion resistance.

Our solid block Diaphragm Pumps have high chemical resistance due to the machined block side housings and the design featuring no-nut, clean face diaphragms. The diaphragms are chemically bonded rather than needing a nut to join the layers together, this benefits your Diaphragm Pump as the area of penetration from the nut in standard diaphragms is a weak spot prone to leakage.

Powder Pump:

As the name suggests, our AOD Powder Pump is perfect for handling paint and pigments in powder. The Powder Pump is an economical and compact alternative to large powder pumping systems and can also be ATEX-rated for use in hazardous environments.

Flexible Impeller Pumps:

EP Self Priming Flexible Impeller Pump

Flexible Impeller Pumps are types of Positive Displacement Pumps. The operating principle encompasses vanes that rotate. As the vanes rotate and pass the discharge port, the liquid is trapped between the vanes and forced forwards towards the discharge port. Flexible Impeller Pumps are ideal Paint Pumps for dosing and metering applications. They are a great Paint Pump solution for viscous fluids, as well as paint, ink, latex and water-based glue. The benefit of using a Flexible Impeller is the customisable nature of the pump as they can be supplied in varying executions for a range of application and installation requirements.

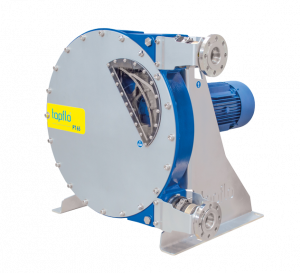

CTI Industrial Centrifugal Pump:

Industrial Centrifugal Pump

Our CTI Pump is the perfect Paint Pump as it has a high mechanical and corrosion resistance for handling solvent-based paint, water-based paint, ink and glue. The CTI Industrial Centrifugal Pump can also be ATEX-rated, making it ideal for use in hazardous environments. The Centrifugal Pump’s casing must be filled with fluid before the pump can be started. As the impeller rotates, it forces liquid through the pump which creates a low-pressure point inside the pump to create centrifugal force that draws liquid into the pump housing.

MDU Units:

Mobile Decanting Unit (MDU)

Our MDU units offer convenience in transporting large paint containers within your facility. Our Mobile Decanting Units seamlessly integrate a Tapflo Air Pump and Pneumatic Batch Controller into a purpose-built trolley, accommodating containers of 20L, 25L, or 205L.

Pneumatic Mixing and Emptying System:

Pneumixer

An accessory that has been specifically developed for the Print and Paint industry is the Pneumixer System. It provides enclosed product handling, reduced product spillage and contamination, keeping applications secured in their container. They are constructed from Stainless steel 316 and Polypropylene as standard and are available for all Tapflo pump sizes from 1/2″ up to 2″.

The Print, Paint and Varnish industry is an intricate one that demands reliability and precision. Our range of Paint Pumps, from Peristaltic Pumps to Diaphragm Pumps, Flexible Impeller Pumps and even Mobile Solutions, are designed to empower your operations.