At Tapflo UK, we pride ourselves on delivering the most reliable and innovative pump solutions to our customers across a range of industries. This commitment to excellence is enhanced by our partnership with Italian manufacturer, Liverani, a company with over 70 years of experience in producing high-quality pumps for the Food, Dairy, Cosmetic, Pharmaceutical, and Chemical industries.

Together with Liverani, we offer an expanded range of pumps that are versatile, reliable, and capable of handling even the most challenging applications, particularly those involving delicate, viscous fluids, and solids in suspension.

Who Are Liverani?

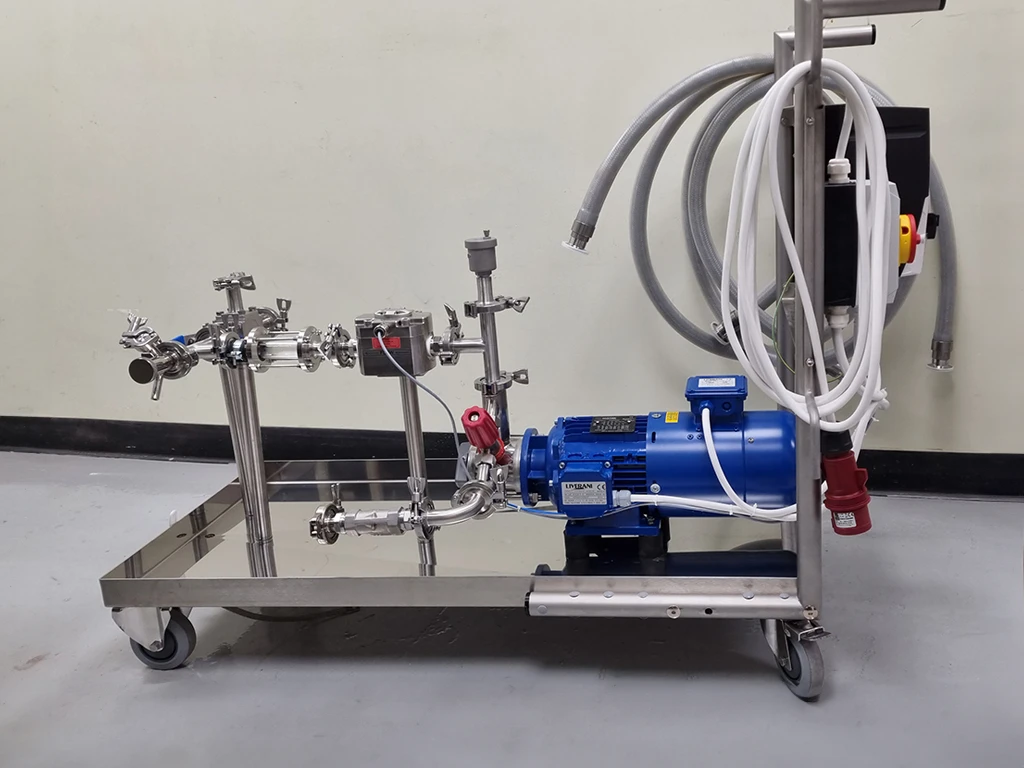

Founded in the 1950s, Liverani has established itself as a leader in the design and production of Flexible Impeller, Self-Priming Liquid Ring, Single Screw, and Volumetric Gear Pumps. Their pumps are known worldwide for their robust construction, ease of use, and low maintenance, making them ideal for numerous applications across varied sectors. Liverani’s products are manufactured to CE Standards, ensuring the highest quality and compliance with global regulations.

Industries Served

Liverani Pumps find application in various industries, with their Flexible Impeller Pumps being particularly well-suited for:

- Food and Beverage: Transferring fluids such as fruit juice, wine, dairy products, syrups, and brine, these pumps ensure hygiene and product integrity

- Cosmetics and Pharmaceuticals: Perfect for handling creams, shampoos, and delicate liquid formulations where low-shear and gentle fluid transfer is required

- Chemical Processing: With a strong resistance to chemicals, these pumps are ideal for transferring inks, paints, detergents, and water-based glues

- Marine and Agriculture: Used for seawater, diesel, and liquid fertilisers, the durable design of these pumps ensures longevity in tough environments

Liverani Pump Range

Liverani Pumps are versatile and designed for multiple industries, with a focus on high performance and easy maintenance. Below, we highlight some key pump types and their applications:

Flexible Impeller Pumps:

Industries: Food & Beverage, Cosmetics, Pharmaceuticals, Chemicals

Applications: These pumps are perfect for handling delicate fluids such as wine, milk, fruit juices, creams, and cosmetic liquids. With low shear operation, they preserve the integrity of products, making them ideal for applications where fluid quality is crucial

Key Benefits of Flexible Impeller Pumps:

- Self-priming up to 6 meters

- Can handle solids in suspension (up to 25mm)

- Reversible operation for efficient tank-to-tank transfers and cleaning

- Customisable for specific industry needs, including FDA-compliant materials

- Smooth, pulse-free flow for precise dosing and filling

Self-Priming Liquid Ring Pumps:

Industries: Food, Dairy, Chemical, Agriculture, Marine

Applications: Particularly well-suited for transferring clear fluids in applications such as milk, syrups, detergents, and even seawater. Their reversible operation makes them useful in the marine industry, and they can handle liquids with dissolved gases or those with discontinuous availability

Key Benefits Liquid Ring Pumps:

- Can run dry, making them highly reliable for intermittent flow processes

- Reversible flow, ideal for cleaning systems

- Available in stainless steel or bronze, ensuring compatibility with various fluids

Single Screw Pumps:

Industries: Chemical, Food, Cosmetics, Wastewater

Applications: These pumps are designed for thick, viscous fluids, and are often used for products like honey, creams, shampoos, and more. They can handle abrasive, corrosive, or shear-sensitive materials with ease, making them ideal for applications where maintaining product integrity is essential

Key Benefits of Screw Pumps:

- Can handle highly viscous fluids (up to 50,000 cPs)

- Pulsation-free operation, essential for accurate dosing and filtration

- Excellent performance even at low speeds for gentle product handling

Volumetric Gear Pumps:

Industries: Lubricants, Fuel, Dairy, Oil

Applications: Liverani’s Gear Pumps are suitable for transferring viscous liquids without solids, such as oils, diesel, and other similar fluids. They offer high performance for continuous industrial operations

Key Benefits of Gear Pumps:

- Suitable for viscous liquids without solids

- Compact and efficient design

- Can handle high pressures, making them ideal for continuous use

Advantages of Liverani Pumps

- Versatility Across Industries: Suitable for handling a wide range of fluids, including viscous, shear-sensitive, and those with suspended solids

- High Solid-Handling Capability: Can handle suspended solids up to 25mm, ensuring efficient pumping of fluids with particulates

- Self-Priming: Capable of self-priming up to 6m from dry, perfect for applications where suction is critical, such as tank emptying or transfer between vessels

- Reversible Operation: Allows bi-directional pumping for convenient tank-to-tank transfer and quick clean-up, supporting CIP (Clean In Place) processes

- Low Shear Pumping: Gentle handling of delicate or shear-sensitive fluids ensures that product integrity is maintained, especially important for applications like food and pharmaceuticals

- Customisable Solutions: Pumps can be tailored to meet specific application needs, with options for impeller materials, motor configurations, mounting styles, and more

- Pulse-Free Flow: Ensures smooth, consistent flow rates, ideal for dosing, filling, and filtration tasks

- FDA-Approved Materials: Available with food-grade impellers such as EPDM and NBR, ensuring compliance with strict hygiene and safety standards for sensitive industries like food and pharmaceuticals

- Durable and High-Quality Construction: Made with AISI 304/316 stainless steel and other robust materials for long-lasting performance and resistance to corrosive or abrasive substances

- Energy-Efficient Operation: Designed for optimal efficiency, reducing energy consumption and operational costs in both high and low-viscosity applications

- Easy Maintenance: Simplified design and high-quality components ensure easy access for cleaning and maintenance, minimising downtime

- Multiple Drive Options: Available in close-coupled, bare shaft, hydraulic drive, and variable speed configurations, offering flexibility to suit different operational setups

Why Tapflo UK Partnered with Liverani Pumps

At Tapflo UK, we continuously look to align ourselves with industry leaders whose values, quality, and innovation match our own. By bringing Liverani’s range of pumps into our portfolio, we are able to offer our customers even greater versatility and reliability across a wider range of industries and applications. Whether you are looking for a pump to handle delicate fluids, viscous liquids, or fluids with suspended solids, Tapflo UK and Liverani have the perfect solution for you.

Contact us today to learn how Liverani Pumps by Tapflo UK can enhance your fluid handling operations!