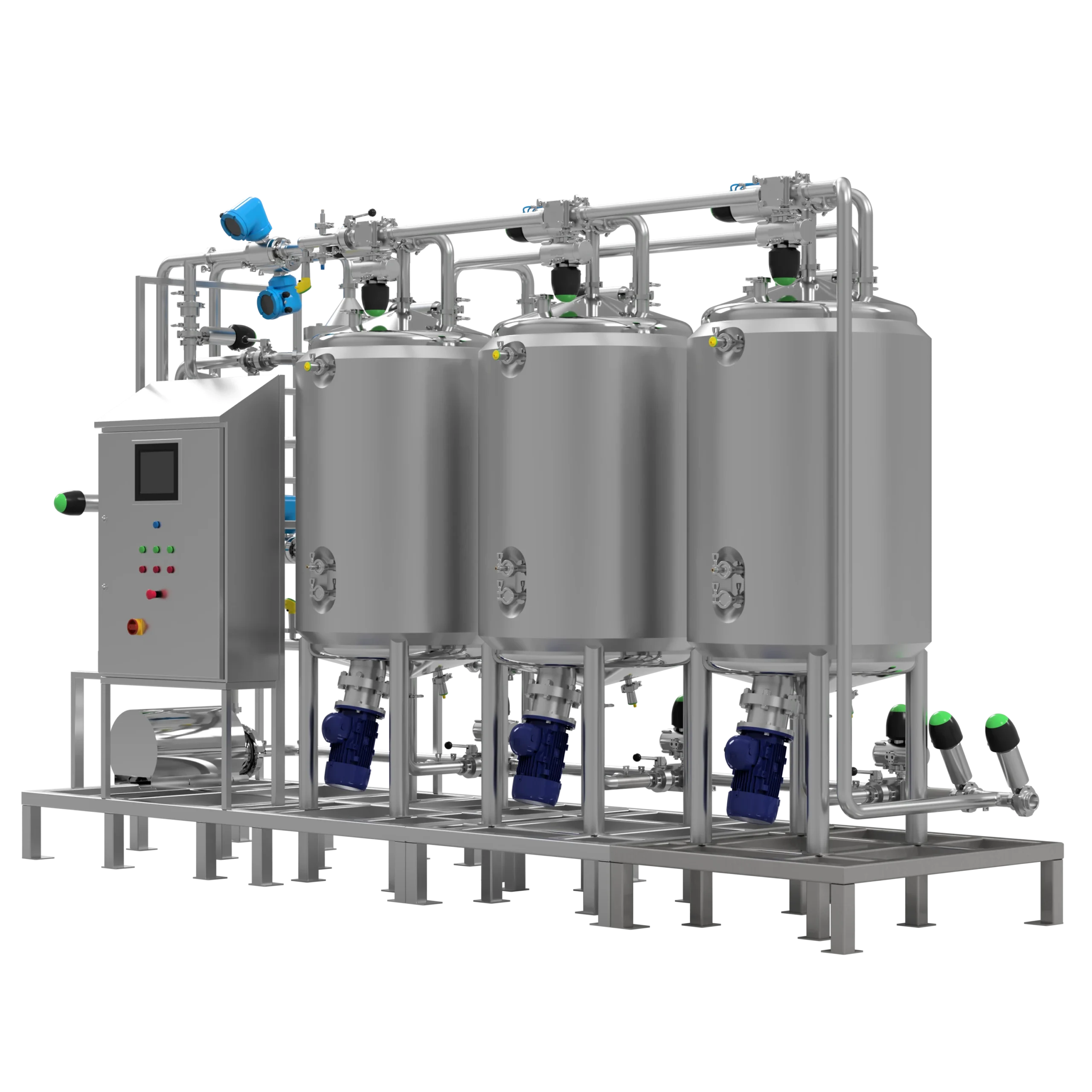

When it comes to ensuring equipment cleanliness, process efficiency, and regulatory compliance, Clean in Place (CIP) Systems are essential. While commonly associated with hygiene-sensitive sectors like Food & Beverage, and Cosmetics, CIP also plays a crucial role in Chemical Manufacturing, Oil & Gas, and Industrial Production, where contamination control, process integrity, and operational efficiency are top priorities.

What is CIP Validation?

Clean in Place (CIP) Validation is the documented process of proving that your CIP Systems consistently clean process equipment, like pipes and tanks, to a predefined standard. The validation process involves testing and verifying that your cleaning procedures effectively remove residues, contaminants, and microbial buildup, ensuring compliance with regulatory and safety requirements. Simply put, CIP Validation confirms that your cleaning process works as intended, delivering repeatable, verifiable cleanliness without requiring equipment disassembly.

Why CIP Validation Matters

Insufficient cleaning validation can lead to product contamination, equipment failure, regulatory penalties, and costly downtime. But despite this, an estimated 80% of daily cleaning in the food industry alone is not properly validated or documented (according to EHEDG yearbook, 2016). Without structured CIP Validation, businesses risk inefficient cleaning cycles, excessive chemical use, and most importantly, compromised product quality.

CIP Protocols for Effective Cleaning

Before diving into validation, it is essential to establish a CIP Protocol, a standardised procedure that defines the factors for effective and repeatable cleaning. A well-designed CIP Protocol includes:

- Cleaning Sequence: The defined order of pre-rinsing, cleaning, post-rinsing, and sanitisation required for your application

- Chemical Agents & Concentrations: Specification of detergents and sanitisers, and their required concentrations

- Flow Rate & Temperature: Setpoints for fluid velocity and heat to optimise residue removal

- Cycle Duration: Required contact time to ensure complete cleaning

- Acceptance Criteria: Defined benchmarks for cleanliness verification (e.g., microbial testing, residue analysis)

CIP Protocols serve as the baseline for validation, ensuring that cleaning cycles are consistent, repeatable, and compliant with your industry’s regulations.

Industries that Rely on CIP Validation

Many industries rely on Clean in Place Systems to ensure hygiene and contamination control, but ensuring these systems perform effectively requires proper validation. Different industries have unique requirements for CIP Validation, each tailored to their specific safety and quality needs. Learn about CIP Systems in our detailed guide, and explore how various industries rely on CIP Validation below:

- Food & Beverage

CIP Validation ensures the removal of allergens, microbial contaminants, and residues, maintaining compliance with FDA, EHEDG, and HACCP standards. Without proper validation, cross-contamination risks increase, leading to potential recalls and safety violations.

- Healthcare & Biotech

In cGMP-regulated environments, CIP Validation is essential for eliminating microbial growth and chemical residues in processing equipment, helping to maintain sterility and quality assurance. Regulatory bodies like the FDA and EMA require stringent validation to ensure drug safety and efficacy.

- Chemical & Industrial Manufacturing

Chemical plants rely on CIP to clean tanks, pipelines, and reactors between production runs, preventing batch contamination and ensuring consistent product quality. ISO 9001 compliance and reduced waste are key drivers for CIP validation in these settings.

- Oil & Gas

CIP is used to clean pipelines, heat exchangers, and process systems, removing chemical deposits that can lead to corrosion and blockages. Correct and thorough validation ensures adherence to ASME and API standards while reducing maintenance costs, ensuring equipment longevity and operational efficiency.

How to Validate Your CIP System Effectively?

A structured CIP Validation process involves several key steps to ensure compliance, efficiency, and cost-effectiveness.

- Establish a Validation Strategy

A robust CIP Validation plan should include:

- A dedicated validation team, including hygiene and chemical experts

- A data-driven testing approach with defined performance criteria

- A schedule that aligns with production cycles

- Performance benchmarks for cleaning effectiveness

Referencing industry standards, such as the EHEDG Guide on Cleaning Validation, helps establish robust validation criteria that include equipment qualification and hazard evaluation, sampling and analytical methods, as well as validation protocols and reporting guidance.

- Implement and Monitor the Cleaning Process

During CIP cycles, data is collected using real-time monitoring tools:

- Conductivity meters to confirm the removal of cleaning agents

- Flow, temperature, and time tracking to verify optimal cleaning conditions

- Automated data logging for validation records and audit compliance

- Analyse Data and Compare with Standards

After execution, collected data is analysed to:

- Compare results against predefined benchmarks

- Identify deviations and determine corrective actions

- Ensure all contaminants and cleaning agents are effectively removed

- Maintain Compliance and Continuous Improvement

Once CIP Validation passes, businesses must document results in a CIP Validation Report that should include:

- The validation master plan detailing the process

- Corrective actions and system improvements

- Protocols for revalidation based on process changes or regulatory updates

- Training programs for operators and quality teams to ensure compliance with best practices

The Real Value of CIP Validation

Effective CIP Validation isn’t just a compliance box ticking exercise. It delivers measurable business benefits such as:

- Cost Reduction: Reduces water, energy, and chemical waste

- Increased Efficiency: Minimises downtime with optimised cleaning cycles

- Regulatory Compliance: Meets industry standards to avoid legal risks

- Product Quality Assurance: Ensures consistent product integrity

- Sustainability: Lowers environmental impact by reducing waste

Why Trust Tapflo UK for CIP Validation

Our team of CIP specialists provides customised validation solutions designed to optimise performance, compliance, and cost savings. At Tapflo UK, we offer:

- Advanced real-time monitoring tools as well as remote monitoring options for accurate validation

- Industry expertise across various sectors

- Regulatory compliance support for FDA, EHEDG, GMP, ISO, and more

- Custom CIP audits and process optimisation strategies

Don’t leave your cleaning processes to chance. Contact our team today to schedule a CIP Validation Audit and ensure compliance, safety, and optimal cleaning performance every cycle.