Stainless Steel Tanks are the backbone of numerous industries, offering unmatched durability, hygiene, and adaptability. From compact 50L vessels to colossal 180,000L storage solutions, these tanks cater to an array of applications, from brewing and food production to chemical processing and water storage. Read on to learn more about Stainless Steel Tanks, their applications, benefits, and considerations to help you make an informed choice about the tank that’s right for your operations.

Applications of Stainless Steel Tanks

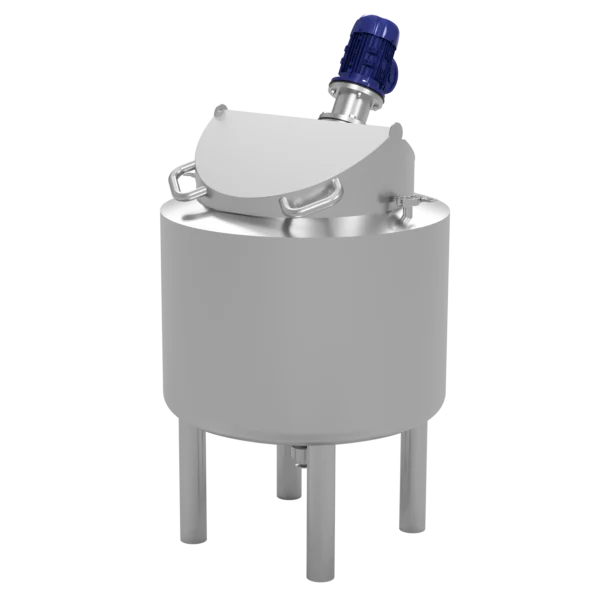

- Mixing Tanks:

Stainless Steel mixing tanks are designed for blending liquids, powders, and other materials. These tanks are equipped with agitators, mixers, or paddles to ensure consistent mixing, handling everything from viscous solutions to delicate emulsions. They are ideal for food preparation, chemical formulations, and pharmaceutical applications.

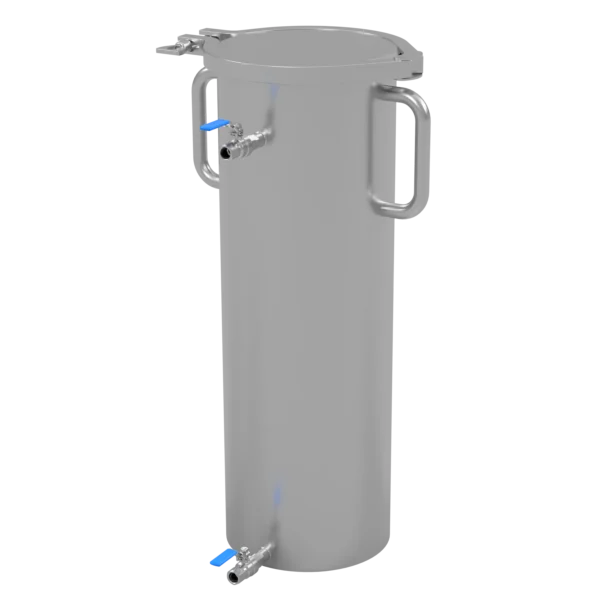

- Powder Storage Tanks:

For industries requiring the storage of bulk powders or granules, Stainless Steel powder storage tanks provide a secure, contamination-free solution. Their smooth surfaces prevent material buildup, ensuring easy cleaning and efficient product flow.

- Chemical Transfer Tanks:

Durable and corrosion-resistant, chemical transfer tanks are essential for safely transporting or storing aggressive substances. These tanks can be fitted with special linings or coatings for added protection and feature custom nozzles or fittings to suit specific processes.

- Food and Beverage Storage Tanks:

Hygiene and safety are critical in food and beverage production. Stainless Steel tanks are used to store, ferment, or process products like sauces, dairy, beer, and wine. Their easy-to-clean surfaces and resistance to bacteria make them the preferred choice for food-grade applications.

- Heated and Insulated Tanks:

For applications requiring temperature control, heated and insulated Stainless Steel tanks are an excellent choice. These tanks are designed with cavity walls, polyurethane foam insulation, or conditioning belts to maintain precise temperatures for sensitive materials such as chocolate, oils, or chemicals.

- Water Storage Tanks:

Stainless Steel water storage tanks ensure durability and hygiene, whether for potable or non-potable water. These tanks resist corrosion and maintain water quality, making them ideal for residential, commercial, and industrial uses, including rainwater harvesting and process water storage.

- Wastewater and Recycling Tanks:

Designed for durability, these tanks handle the storage and treatment of wastewater, slurries, or recycled materials. Stainless Steel’s robustness ensures a long lifespan even in demanding environments, such as recycling facilities or industrial wastewater systems.

- Pharmaceutical and Biotech Tanks:

Precision and sterility are critical in the pharmaceutical and biotech sectors. Stainless steel tanks are widely used for mixing, fermenting, or storing sensitive materials in these applications. Features like electro-polished surfaces and customizable fittings ensure compliance with stringent standards.

Tank Material Grades & Their Benefits

The choice of material for your tank plays an important role in determining its performance, durability, and suitability for your application. Stainless Steel is the most commonly used material due to its exceptional corrosion resistance properties. Here is a closer look at the benefits and strengths of various grades of Stainless Steel, along with other material options available:

316 Stainless Steel:

- Benefits: Renowned for its exceptional corrosion resistance, particularly against harsh chlorides, chemicals, and saltwater. This grade of material is highly durable and can withstand harsh environments, making it ideal for industrial and marine applications

- Uses: Widely used in chemical storage, food and beverage processing, and water tanks exposed to saline or aggressive conditions

- Strengths: High resistance to pitting and crevice corrosion, with excellent hygienic properties due to its smooth surface. Additionally, 316-grade maintains structural integrity in extreme temperatures

304 Stainless Steel:

- Benefits: A cost-effective and versatile grade with good corrosion resistance properties. It is easy to form and weld, making it suitable for a wide range of general applications

- Uses: Commonly found in food and beverage tanks, general-purpose water storage, and industrial applications that do not involve highly corrosive substances

- Strengths: Affordable and reliable, suitable for environments where exposure to extreme chemicals or high-salinity media is minimal

321 Stainless Steel:

- Benefits: Contains titanium which enhances its resistance to intergranular corrosion at high temperatures. Ideal for applications involving prolonged exposure to heat

- Uses: Frequently used in high-temperature industrial processes, such as chemical production and heat exchangers

- Strengths: Excellent thermal stability, maintain strength and resistance in high-heat environments. Ideal for preventing degradation over time

Exotic & Alternative Materials:

- Aluminium: Lightweight and corrosion-resistant, aluminium is suitable for non-corrosive applications or environments where weight savings are essential. Commonly used for storage tanks in transportation or light-duty applications

- Other Stainless Steels: Depending on the application, specialised stainless steel grades with added properties (e.g., duplex stainless steel for high strength and corrosion resistance) are available

- Plastic: There are a variety of plastic materials used in tank manufacturing for specific applications. These include HDPE (High-Density Polyethylene), PP (Polypropylene), PVDF (Polyvinylidene Fluoride), and ETFE-lined or PFA-lined metal tanks. ETFE (Ethylene Tetrafluoroethylene) and PFA (Perfluoroalkoxy Alkane) share similarities with PTFE, offering excellent chemical resistance and durability, but with slight differences in thermal properties and flexibility

Material Selection Considerations:

- Corrosion Resistance: The level of exposure to corrosive substances, chemicals, or saline environments determines the appropriate grade of material

- Temperature Range: High-temperature processes require grades like 321 Stainless Steel for stability and optimal performance

- Budget and Longevity: Balancing upfront costs with the long-term durability and maintenance of the tank is crucial

- Specific Application Needs: Each industry’s unique requirements, such as hygiene in food processing or strength in chemical storage, will influence material selection

Advantages of Stainless Steel Tanks

- Durability and Longevity: Stainless steel, especially grades such as 316, offers exceptional resistance to corrosion, wear, and environmental factors. This ensures that tanks can endure decades of use, even in challenging industrial settings.

- Hygiene and Safety: The smooth, non-porous surface of Stainless Steel resists bacterial growth, making these tanks ideal for industries requiring stringent cleanliness standards. Additionally, their chemical resistance capabilities ensure product safety during storage or processing. To maintain optimal hygiene, these tanks are compatible with Clean in Place (CIP) Systems, allowing for efficient and thorough cleaning without the need for manual intervention. CIP ensures that every corner of your tank is cleaned and sanitised, meeting even the most rigorous cleanliness standards. Learn more about our CIP Systems to explore a system suited to your needs.

- Customisation Options: From bespoke fabrication to integrated features, Stainless Steel tanks can be tailored to specific needs. Options include heating elements, insulation, agitation systems, or mountings for pumps, level sensors, and mixers.

- Versatility in Applications: Stainless Steel tanks accommodate a range of sizes and configurations, from portable 50L vessels to insulated 20,000L tanks designed for temperature-sensitive liquids. Whether for potable water storage, chemical processing, or bespoke applications, their versatility is truly unmatched.

- Aesthetic and Functional Finishes: Choose from finishes like 2B mill, bead blasting, mirror polishing, or electro-polishing. Not only do these finishes enhance aesthetics, but they also improve the functionality of the tanks by aiding in maintenance and cleaning.

Considerations when Choosing your Stainless Steel Tank

Material Grade:

- 316 Stainless Steel: Ideal for environments exposed to saltwater, acids, or chemicals

- 304 Stainless Steel: A cost-effective option for general use

- Other Materials: Options like 321 Stainless Steel or aluminium may be suitable for specialised applications

Capacity and Dimensions:

- Tanks are available in sizes ranging from 250L to 20,000L, with increased capacities available on request

- Consider space constraints, usage volume, and future scalability when selecting tank size

Insulation and Temperature Control:

- Tanks can include polyurethane foam insulation and cavity walls for minimising heat loss

- For temperature-sensitive processes, options like conditioning belts with glycol circulation are available

Customisation and Features:

- Add-ons like access hatches, hinged lids, forklift pockets, and agitators can be integrated to enhance usability

- Consider the specific equipment your tank will need to interface with, such as level sensors or pumps

Compliance and Certifications:

- Ensure your tank meets industry standards such as PED/CE certifications for pressure equipment

- Verify hygiene and safety compliance for food-grade or potable water applications

Customisation Options

At Tapflo UK, we take pride in offering bespoke solutions that go far beyond standard tanks. Whether it’s industrial trolleys, integrated pipework, or tailored skids, our expertise ensures that every product is designed to fit seamlessly into your specific processes. From one-off prototypes to full-scale production runs, we’re here to enhance your operations and optimise efficiency, no matter the scale!

Our Stainless Steel Tanks are available in a wide range of shapes, sizes and configurations to meet diverse operational requirements. Some examples of Tanks we’ve supplied recently include:

- 50L Flat Open Top Threaded Pot: A smaller tank with a flat open top and threaded fittings, ideal for small-scale applications or manual mixing

- 250L Angled Grated Open Lid: A mid-sized tank with an angled design and a grated lid for ventilation or safe access, commonly used for semi-open processing or temporary storage

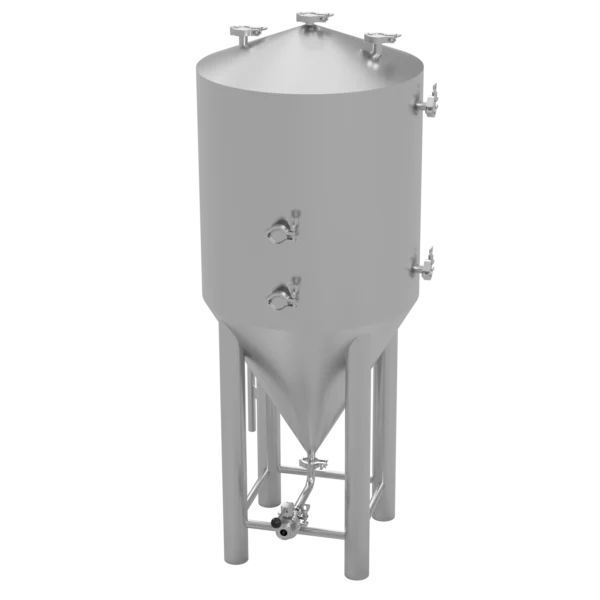

- 250L High Angle Conical: A cone-shaped tank with a steep angle, designed for efficient draining of liquids or slurries, often used in food, beverage, or chemical applications

- 1000L Insulated Conical: A larger conical tank with insulation, perfect for maintaining the temperature of the media, such as in brewing or chemical industries

- 1000L Insulated Conical High Angle: Similar to the Insulated Conical, but with a steeper conical base for better drainage of viscous or particulate-heavy liquids

- 2000L Insulated Dished: A tank with a dished (rounded) base, insulated for temperature control. Dished bottoms are typically chosen for their strength and ease of cleaning

- 20,000L Horizontal Flanged: A large horizontal tank with flanged connections, suitable for bulk storage or transport of liquids, particularly in industrial applications

Every detail, from the selection of premium-grade materials to the precision of our welding and polishing processes, delivers superior functionality and longevity. Whether you need a compact 250L tank for a microbrewery or a 20,000L tank for large-scale chemical storage, you can trust our tanks to provide consistent performance and durability.

Ready to explore your options? Whether you’re looking for a standard water tank, a heated process vessel, or a fully customised storage solution, Stainless Steel Tanks offer unmatched versatility and reliability. Contact the Tapflo UK team today to discuss your requirements and let us help you create the perfect solution for your needs.