In response to increasing demands for efficiency and reliability in food manufacturing, a leading food producer approached Tapflo UK for a bespoke solution to automate the decanting of vinegar and pickling liquids. The client needed a system that streamlined their production flow, minimising downtime and manual intervention. Our Engineering Team developed a Fully Automated IBC Decanting System featuring our T80 Sanitary Diaphragm Pump, which met the client’s stringent hygiene standards while ensuring robust, efficient operation.

Application Details

Our client, a prominent food manufacturer, was processing around 4,000 litres of vinegar daily using a single IBC. Frequent manual changeovers were required, resulting in complete production line stoppages that hindered operational efficiency. The IBCs were also stored in a low-traffic area, which meant less frequent monitoring and occasional non-operation during manual interchanges. With these challenges, the need for a reliable and fully automated solution became critical to maintaining productivity and reducing downtime.

Components of the System

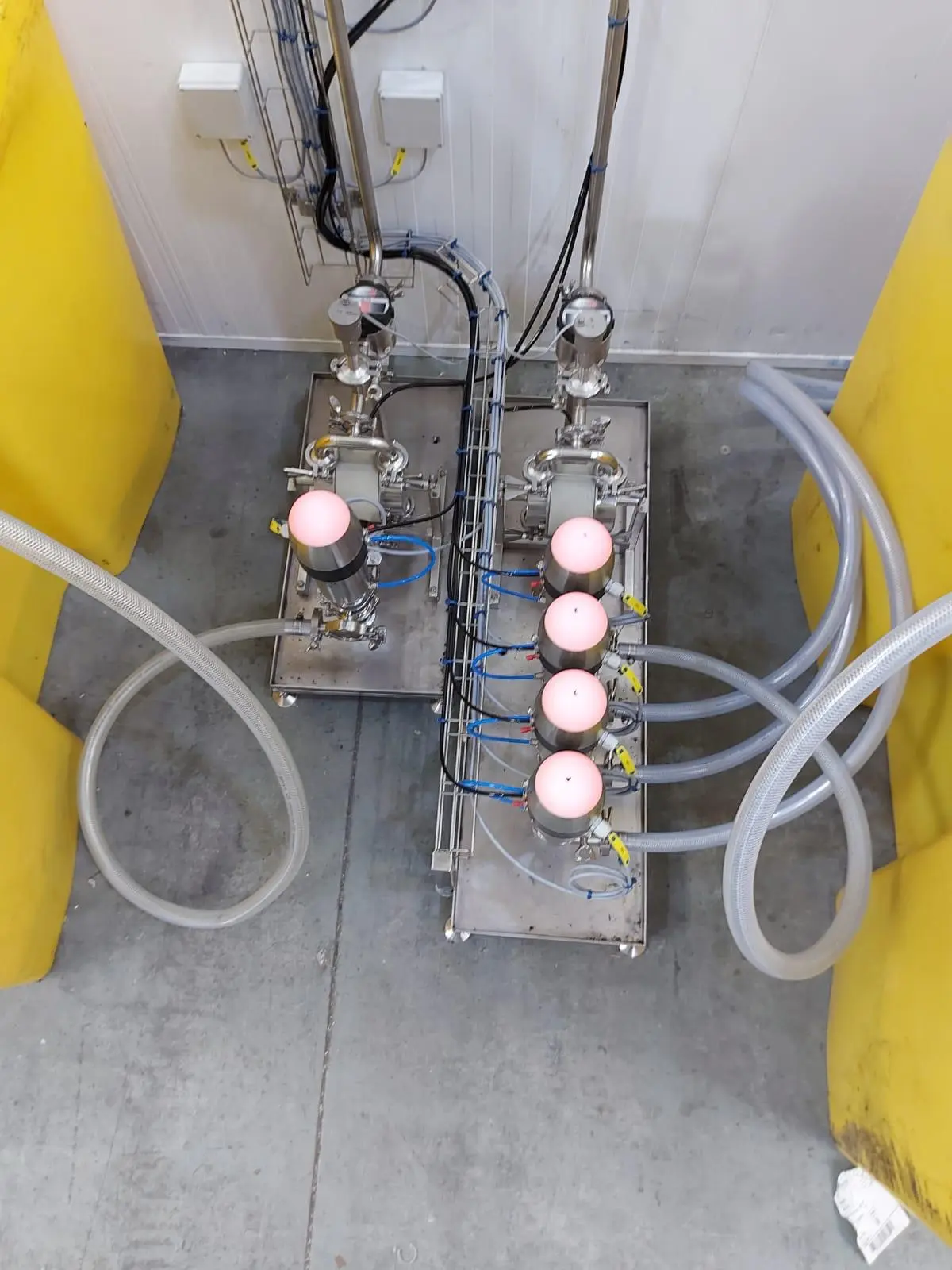

Tapflo UK’s Engineering Department designed a custom IBC decanting system that integrates two distinct processes: one for dosing vinegar onto rice and another for pickling vegetables. Key components of the system included:

- 4x IBCs in a Line: This configuration allows for continuous processing of the entire day’s vinegar supply without interruption, eliminating the need for frequent manual changeovers

- T80 STT Sanitary Diaphragm Pump: The T80 was selected for its robust performance in hygienic applications, meeting the client’s sanitation standards essential for food production. This pump is designed specifically for acidic substances, ensuring durability and reliability in processing vinegar and pickling liquid

- VEGAPULS21 Radar Sensors: These sensors monitor vinegar levels above each IBC, allowing the system to automatically transition between containers as needed, ensuring consistent supply without manual oversight

- Valve Manifolds: Connected to the IBCs, 4x valves automatically switch between containers based on real-time vinegar levels, improving operational reliability

- Custom Control Panel: Designed to enable centralised control of the entire system, the panel allows operators to monitor and manage the flow with ease

- VEGABAR29 Pressure Switches: Installed on the discharge side, these switches automatically shut off the line if pressures become too high, providing added safety and deadhead protection

Benefits of the Solution

The implementation of the Fully Automated IBC Decanting System delivered several substantial benefits for the client:

- Increased Efficiency: The automated system eliminated the need for manual IBC changeovers, enabling uninterrupted production, which improved efficiency and throughput

- Enhanced Production Reliability: The integration of real-time monitoring and automated switching between IBCs reduced downtime and ensured consistent operation, meeting the client’s production demands without delays

- Optimised Hygiene and Safety: The T80 Sanitary Diaphragm Pump, designed for hygienic applications, ensured the system met the necessary sanitation requirements for handling acidic food substances, while the pressure switches provided additional safety by preventing pressure build-up

- Improved Workflow: The custom control panel streamlined the process, allowing operators to monitor, adjust, and manage the system seamlessly, leading to better workflow management

Tailored Support from Tapflo UK

Through careful engineering and automation, Tapflo UK successfully addressed the challenges faced by the food manufacturer, providing a robust and efficient IBC decanting system. The project demonstrates Tapflo UK’s capability to deliver custom-engineered solutions that align with both operational efficiency and high standards of hygiene, underscoring our commitment to reliability and quality in food manufacturing processes.

In need of a bespoke solution for your operations? Get in touch with our team today for tailored application support.