Finding the right pumps for viscous food products can be challenging. Whether you’re processing honey, molasses, peanut butter, or any other thick, sticky food substance, selecting the appropriate pump is crucial for maintaining efficiency, hygiene, and most importantly, product integrity. In this guide, we’ll cover the challenges of pumping viscous food ingredients, the importance of hygiene, and our recommended pumps and systems for these demanding applications.

Why Pumping Thick, Sticky Foods is Difficult

Pumping highly viscous food products like honey, peanut butter, molasses, caramel, sauces, and purees pose unique challenges when it comes to pumping:

- High Viscosity: Thick foods flow slowly and require pumps with strong suction capabilities to ensure continuous flow

- Small Solids in Suspension: Ingredients like fruit purees, jams or sauces may contain chunks or seeds, which can clog certain pump types

- Sticky Nature: Many viscous products (like molasses and jam) are sticky, leading to issues with seals and mechanical parts sticking during standstill periods, causing leaks or wear when restarted

- Temperature Sensitivity: Some products, like chocolate syrup or honey, can become more viscous at lower temperatures, requiring heating systems to maintain fluidity

The Importance of Hygiene in Food Processing

When dealing with food products, maintaining hygiene is vital to ensure product safety and quality. All pumps used in food processing must comply with strict hygiene standards, such as being FDA-approved and designed for easy cleaning. Pumps with smooth internal surfaces prevent bacterial build-up, while Clean in Place (CIP) systems ensure that your equipment stays free from residue that could contaminate the next batch.

Hygienic certifications like FDA approval, EHEDG (European Hygienic Engineering & Design Group) certification, and 3-A Sanitary Standards ensure that food-grade pumps and systems are built to the highest sanitary standards. These certifications guarantee that pumps have smooth, crevice-free internal surfaces, preventing bacteria build-up and making cleaning easier through CIP (Clean in Place) procedures.

Our guide on the importance of using Sanitary Pumps for critical, high-risk applications covers all you need to know to ensure ultimate hygiene levels for your operation.

Recommended Pump Types for High-Viscosity Food Products

We offer a variety of pumps suited for thick food substances, each with features designed to handle different aspects of viscous, sticky ingredients. Here’s an overview of our recommended pumps for viscous food products:

- Ideal for handling thick, viscous fluids with small solids in suspension, such as fruit purees, sauces, and jam with seeds

- Smooth, near-pulseless flow at high discharge pressures

- Exceptional cleanability for hygiene-sensitive environments

- Resistance to abrasion from solids, thanks to robust seal protection and optional flushing systems

- For products like molasses, peanut butter, or chocolate syrup, Peristaltic Pumps offer a gentle pumping action that reduces shear and preserves product integrity

- Can handle extremely viscous and sticky substances without clogging

- Feature a simple design with minimal internal parts, making them easy to clean and maintain

Air-Operated Double Diaphragm (AODD) Pumps:

- Diaphragm Pumps are highly versatile and can be adapted for products like honey, syrup, or ketchup

- Moving high-viscosity substances with minimal risk of contamination

- Offering a self-priming function, which is useful for thick, hard-to-move products

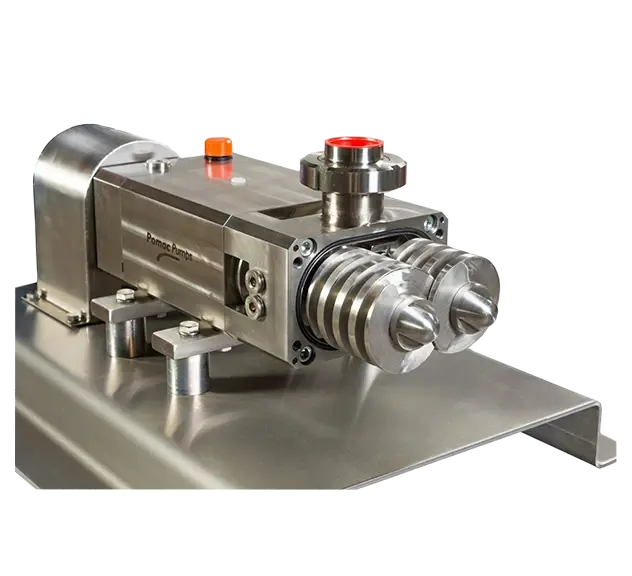

- Twin Screw Pumps are ideal for viscous substances such as buttercream, caramel, and pasta sauces

- Excellent handling of thick liquids with solids

- Ability to function at both low and high viscosities, providing flexibility across a wide range of food processing applications

- Designed to offer hygienic handling with CIP systems

Sanitary Progressive Cavity Pumps:

- Best suited for products like yoghurt, cream cheese, and dough, Progressive Cavity Pumps excel in moving highly viscous products while maintaining a smooth, consistent flow

- Offer a gentle, low-shear pumping action to protect product texture and quality

- Ideal for transporting products over long distances without pulsation

- For less viscous products like sauces, syrups, and jams, Flexible Impeller Pumps provide a balance of gentle handling and effective flow control

- Handle a wide range of viscosities with ease

- Offer fast disassembly for cleaning purposes, supporting hygiene protocols

- These pumps are perfect for dense, sticky products like Nutella, marmalade, and tahini

- Precise flow control for difficult-to-move fluids

- Self-priming action, allowing easy transfer of viscous products

A Tapflo UK Top Tip:

While Centrifugal Pumps excel in a range of Hygienic applications, they are not recommended for high-viscosity food products as they are designed for low-viscosity fluids and could struggle to handle anything over 200 cPs. In applications requiring up to 5,000 cPs or more, like with peanut butter or molasses, Centrifugal Pumps can’t generate enough pressure or flow, leading to inefficiencies and potential clogging. For these reasons, Positive Displacement Pumps are a better fit for viscous food substances.

Systems & Accessories for High-Viscosity Food Products

High Viscosity Systems (HVS):

Our High Viscosity Drum Unloading Systems are designed for the efficient, hygienic removal of thick, sticky products from drums. Each system removes up to 99% of product, ensuring minimal waste and reliable performance.

- HVS Drum Unloading Machine: Ideal for pastes like tomato puree, tahini, and resins, this system features a Sanitary Air-Operated Diaphragm Pump and accommodates solid particles up to 42mm. It offers an ATEX-rated option for hazardous environments and surface finishes up to Ra <0.5 for enhanced hygiene

- HVS Quattro Drum Unloading Machine: Designed for high-volume applications, this system unloads at 400 l/min and simplifies drum switching with an articulated arm. It’s ideal for operations handling multiple drums (up to 4 at a time) and can operate in both automatic and manual modes

- HVS Flexi Drum Unloading Machine: Best for low-to-moderate volume applications, this unit features a Hygienic Progressive Cavity Pump for liquids up to 100,000 cPs, making it perfect for precise unloading into filling or packing lines

Heating Jackets:

For products that become more viscous when cooled (like honey or caramel), heating jackets are a great solution to keep the product flowing without solidifying in the pump. These jackets circulate heated water around the pump’s wetted parts, ensuring consistent temperature and flow.

Flushed Mechanical Seals:

Well-suited to sticky and abrasive fluids, designed to reduce wear and keep the mechanical face seal clean.

How to Avoid Clogging when Pumping Thick Foods

Clogging is a common issue when pumping thick, sticky products like molasses, chocolate syrup, and mayonnaise. To avoid this, consider the following:

- Correct Pump Sizing: Ensuring your pump is correctly sized for both the viscosity and the presence of solids will help maintain smooth operation

- Heating Jackets: Using a pump with a heating jacket helps keep products warm and fluid, reducing the risk of solidification

- Flushing Systems: Pumps handling sticky substances may require regular flushing to prevent build-up and ensure smooth operation

Key Takeaways

- Hygiene is Critical: All pumps MUST comply with strict food safety standards, ensuring easy cleanability and preventing contamination

- Viscosity Matters: High-viscosity food products require specialised pumps designed to handle thick, sticky ingredients

- Choose the Right Pump: We offer a wide range of pump types, including Sanitary Lobe Pumps, Peristaltic Pumps, AODD Pumps, and Twin Screw Pumps to name a few, each suited to different food products

When choosing a pump for viscous food products, there is no one-size-fits-all solution. The type of pump you need will depend on your specific product, the viscosity, the presence of solids, and the desired flow rate. In addition to Lobe, Peristaltic, and Twin Screw Pumps, we also offer Sanitary Diaphragm Pumps, Aseptic EHEDG Diaphragm Pumps, Hygienic Progressive Cavity Pumps, and Low/High-Pressure Peristaltic Pumps.

If you’re looking for a reliable solution for pumping viscous food products like honey, peanut butter, sauces, or chocolate syrup, contact our team today to find the perfect pump for your needs. We provide expert guidance to ensure that you select the best pump for your application, optimising both efficiency and product quality for the consumer.