In winemaking, selecting the right pump is crucial to ensuring product quality, operational efficiency, and hygiene. A Wine Pump plays an essential role throughout various stages of the wine-making process, including the transfer of delicate fluids like grape must and fermented wine. This guide covers the key factors you need to consider when choosing a Wine Pump and highlights the best pump options available for the Oenological industry.

Clarifying the 6-Step Winemaking Process

Harvesting: During the harvest, grapes are picked and transported to the winery. Pumps may not be used at this point, but they become critical after the grapes are received at the winery. However, in larger operations, pumps could be used to transfer grape must or juice after initial crushing

Destemming: After the harvest, grapes are destemmed to remove stems and leaves. The grapes and juice (must) are separated from the stems using a destemming machine. Here, pumps are often used to transfer the grape must to the next processing stage, especially in large-scale operations. The pump system must be gentle to avoid damaging the grapes and altering the flavour profile

Crushing/Pressing: After destemming, grapes are either crushed (for red wines) or pressed (for white wines) to release their juice. Pumps are critical at this stage to transfer the juice or must from the crusher or press into fermentation tanks. Different types of pumps, such as Must Pumps or Peristaltic Pumps, are used to ensure a smooth transfer of the delicate must without compromising quality:

- For red wine: The grape skins, seeds, and juice (“must”) are pumped into fermentation vessels

- For white wine: The juice is pressed off the skins and pumped into tanks for fermentation

Fermentation: During fermentation, the must is converted into wine by yeast, which transforms the sugars into alcohol. Pumps are often used during this stage for “pump-overs” (pumping wine over the grape skins in red wine production to extract more flavour and colour). Pumps can also be used to control temperature by circulating wine between fermentation vessels or for transferring the fermented wine into other containers:

- Pump-overs: Pumps are essential for moving the wine to mix the must and skins, ensuring even fermentation

- Transfers: After fermentation, pumps are used to move the wine into new tanks for clarification

Clarification: In this stage, wine is clarified to remove solids like dead yeast cells and grape particles. Pumps are crucial for racking, where wine is pumped from one vessel to another to leave behind sediment (lees). Pumps are also used in filtration processes, which ensure a clear wine:

- Racking: Gentle pumps are used to transfer wine without disturbing the sediment at the bottom of tanks

- Filtration: Some pumps may be integrated into filtration systems to remove any remaining particles or unwanted materials

Aging & Bottling: In the final stage, the wine is aged in barrels or tanks and then bottled. Pumps are used to transfer wine from barrels to blending tanks or from storage tanks to bottling lines. In bottling, pumps must provide a steady, accurate flow to ensure proper filling without introducing oxygen, which can spoil the wine:

- Aging transfers: Wine is pumped from one vessel to another for aging or blending

- Bottling: Pumps ensure that the wine is moved into bottles efficiently and cleanly, without contamination or oxidation

Key Applications of Wine Pumps

Wine Pumps are integral to several stages of the winemaking process. Some common applications include:

- Transferring wine between fermentation tanks

- Filling and emptying tanker trucks

- Pumping grape must during blending

Selecting the right pump for each stage will help maintain the integrity of the wine and optimise operational efficiency.

Important Considerations when Choosing a Wine Pump

When selecting a pump for your winery, it’s essential to keep several key factors in mind:

- Food-Grade Compliance: Always ensure that your pump is FDA-approved and suitable for food-grade applications. Wine Pumps should be constructed from high-quality stainless steel and feature food-safe seals to prevent contamination

- Shear-Sensitive Handling: Wine and must are delicate products. Choose a pump that can move the liquid without causing agitation or damage to the product. Excessive shear can alter the flavour and quality of the wine

- Ability to Handle Solids: Must, the residue of crushed grapes, contains solids such as skins and seeds. Your pump must have strong suction lift and be capable of transferring solids without clogging or losing efficiency

- Pulsation-Free Operation: Air introduction during the wine transfer process can negatively affect both the alcohol content and taste. Look for pumps that offer smooth, pulse-free flow to minimise froth and oxidation

Tapflo UK Recommends these Pumps for Wineries

Several types of pumps are well-suited for winery applications, each offering unique benefits depending on your specific needs.

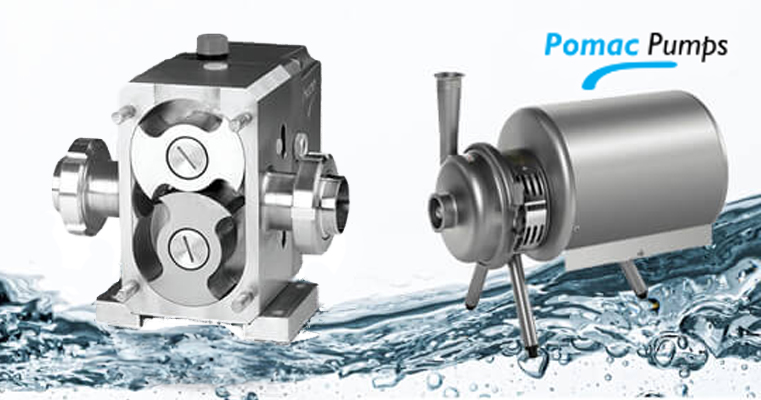

Flexible Impeller Pumps: Designed with the Oenological industry in mind, Flexible Impeller Pumps are ideal for transferring both must and wine. The flexible vanes of the impeller allow the pump to handle solids gently while providing pulse-free, low-speed operation.

Benefits:

- FDA-compliant for sanitary applications

- Low cost and low maintenance

- Customisable and compatible with automatic barrel-filling kits

- Pulse-free operation for smooth, oxidation-free transfers

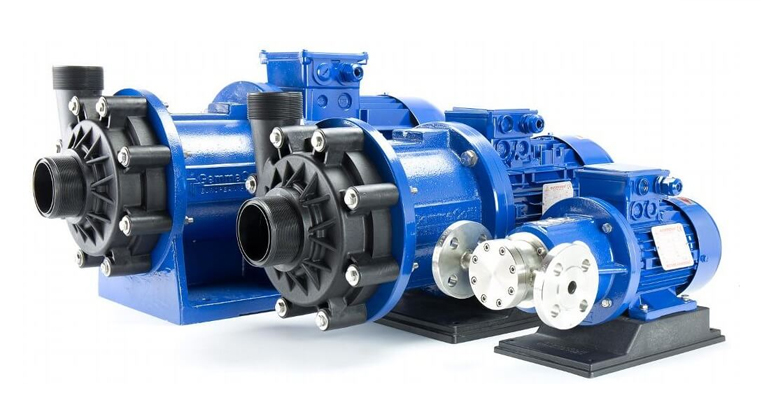

Peristaltic Pumps: Peristaltic Pumps are Positive Displacement Pumps that excel at transferring delicate fluids. Their design ensures only the hose comes into contact with the product, which is especially useful when handling must or wine.

Benefits:

- Self-priming and dry-running capabilities

- Ideal for thick fluids and high-suction lift applications

- Adjustable roller pressure to prevent product damage

- Longevity of hoses (30% longer life than standard)

Drawback: Peristaltic Pumps can produce pulsation in the flow, but this can be mitigated with a pulsation dampener.

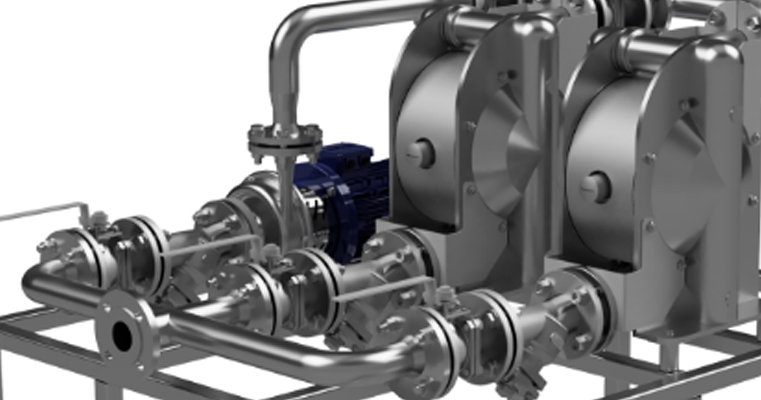

Sanitary Diaphragm Pumps: Diaphragm Pumps are versatile, air-powered pumps popular in many industries. They are highly suitable for wineries due to their ability to transfer large volumes of fluid without compromising quality.

Benefits:

- Low maintenance and easy cleaning

- Gentle product handling with sealless design

- Capable of dry-running and self-priming

- LEAP Technology reduces energy consumption by up to 70%

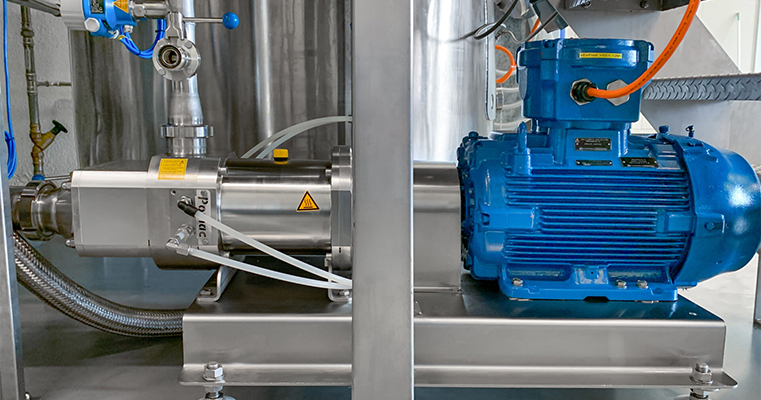

Sanitary Lobe Pumps: Lobe Pumps are known for their efficiency and ability to handle shear-sensitive fluids. They are ideal for wine transfer, filtration, and bottling due to their near-pulsation-free operation.

Benefits:

- Supports CIP (Clean in Place) and SIP (Sterilise in Place) for optimal hygiene

- Minimal downtime and low maintenance

- Can handle delicate wine transfer without agitation or oxidation

- Self-priming and capable of dry running for short periods

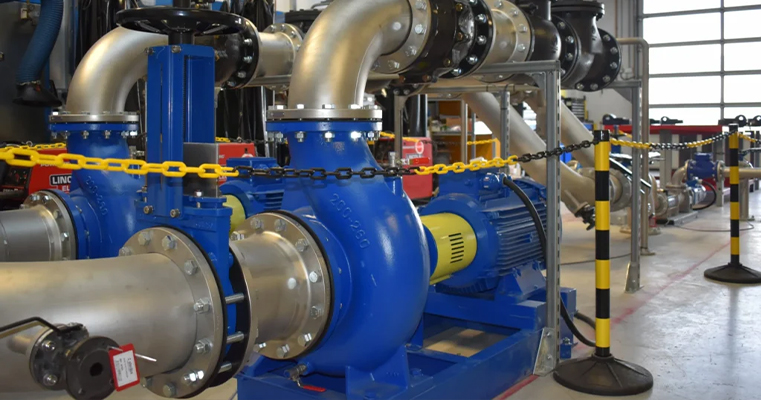

Why Shouldn't I Use a Centrifugal Pump for Wine?

While Centrifugal Pumps are common in beverage production, they are not recommended for winemaking due to their potential to introduce oxygen during transfer, leading to oxidation and altering the taste of the wine. For delicate fluids like wine, it’s better to use pumps that minimise agitation and exposure to air.

Other Considerations for Winery Pumps

In addition to choosing the right pump type, keep these factors in mind:

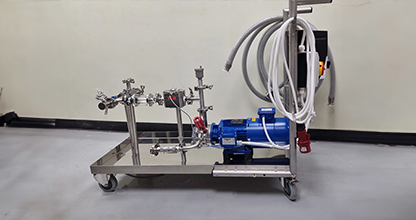

- Portability: Pumps that are easily portable allow for flexibility in operations across different areas of the winery

- Ease of Operation: The pump should be user-friendly and easy for winery personnel to operate and maintain

- Cost Effectiveness: While quality is critical, it’s essential to choose a pump that offers value for money and reduces long-term maintenance costs

Common Questions about Wine Pumps

What is Grape Must?

Grape must is a combination of freshly crushed grape juice, skins, seeds, and stems (pomace) that forms during the initial stages of winemaking. It is a thick, viscous liquid, typically around 2000 CPS on the viscosity scale, compared to the low viscosity of fermented wine (1 CPS). The ability to handle both must and wine requires pumps with specialised design and capacity.

Must Pump vs. Wine Pump: Which One Do You Need?

The distinction between a Must Pump and a Wine Pump comes down to the type of liquid being moved and the pump’s design.

- Must Pumps: These pumps are designed for handling fluids with solids, like grape must. They require wider tubing, larger pump heads, and heavy-duty motors to handle the high viscosity and solid content of must

- Wine Pumps: These pumps are better suited for low-viscosity fluids such as fermented wine. They are often used for processes like filtration and bottling, where gentle, pulse-free transfer is critical to maintaining product integrity

For more information on Wine Pumps and how our systems and solutions can assist with your Oenological needs, contact us today.