At Tapflo UK, we’re on a mission to provide cutting-edge fluid-handling solutions that meet the varied needs of our clients. Our partnership with Nova Rotors, a leading Italian manufacturer of Progressive Cavity and Wobble Pumps, allows us to offer pumps that are not only reliable but also highly customisable for various industrial and hygienic applications.

Advantages of Nova Rotors Pumps

When selecting a pump for your application, Nova Rotors’ pumps offer several distinct advantages:

- Modular Design for Cost Efficiency: Pumps are designed with modularity in mind, meaning that components such as seals, stators, and rotors are interchangeable across different pump types. This significantly reduces stocking costs and simplifies maintenance, making it easier to keep your operations running smoothly

- Long-Pitch Rotor Design for Energy Efficiency: The Diamond Series pumps are designed with a long-pitch rotor, reducing energy consumption by up to 20% compared to traditional pumps. This design not only cuts operational costs but also reduces the starting torque, enhancing the overall efficiency of your systems

- Customisable to Specific Application Needs: Whether you’re handling viscous fluids, abrasive media, or need a pump for a challenging installation environment, Nova Rotors offers customisation options that ensure your pump is perfectly suited to your application. From vertical units for tank immersion to specialised bridge breakers for tough materials, we offer a pump for every need

Progressive Cavity Pumps that Meet Stringent Industry Standards

Nova Rotors’ pumps are built to excel in demanding environments, and meet the highest industry standards:

- Oil & Gas Applications: Certified to API standards, Nova Rotors’ pumps are designed to withstand the harsh conditions of the Oil & Gas industry, ensuring reliability and performance in critical applications

- Safe Operations in Hazardous Environments: With ATEX certification, these pumps are suitable for use in explosive atmospheres, providing peace of mind in environments where safety is paramount

- Hygienic Applications in Food and Pharmaceuticals: EHEDG-certified and 3A-approved, the hygienic design of Nova Rotors’ pumps makes them ideal for the Food, Pharmaceutical, and Cosmetics industries. These pumps are designed to prevent bacterial build-up and ensure optimal cleanability, making them compliant with strict hygiene standards

Progressive Cavity Pump Recommendations by Application

Our range of Progressive Cavity Pumps by Nova Rotors is tailored to meet the specific needs of various industries. Below are our top recommendations for specific applications:

Oil & Gas:

- Recommended Pumps: Industrial Progressive Cavity Pump

- Overview: Nova Rotors has extensive experience in the Oil & Gas sector, offering solutions for both low and high-viscosity fluids, including those with fibres, adhesives, or varying temperatures. The DN, DH, and DV models are engineered to handle the rigorous conditions typical of oil production, refineries, and petrochemical plants. These pumps ensure reliable performance across all stages of storage, feed, and discharge

Waste & Sludge Treatment:

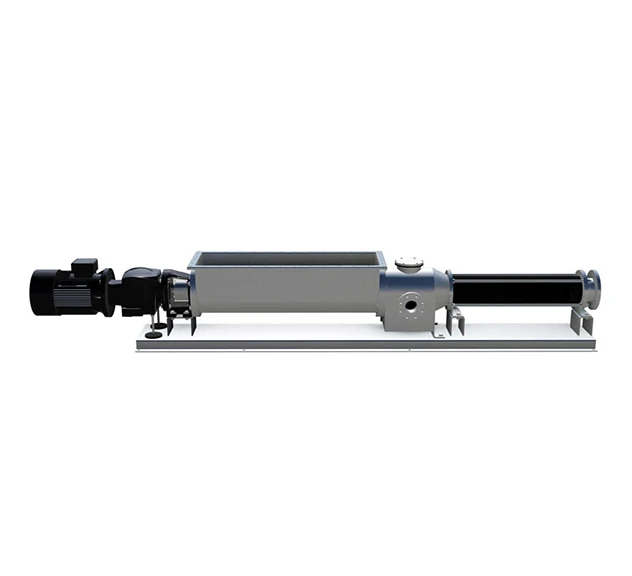

- Recommended Pumps: Double Shaft Hopper Pump

- Overview: Designed for thickened and dewatered sludge with high solids content, Progressive Cavity Pumps excel in handling semi-fluids or plasticising sludges. The DN, DH, DHS, DHB, DHSB, and DV models are specifically built to meet the stringent hygiene standards of sludge treatment plants, providing effective solutions for storage, treatment, and transfer stages

Pulp & Paper:

- Recommended Pumps: Industrial Hopper Pump

- Overview: In the papermaking industry, Nova Rotors’ pumps are tailored for fibrous materials like pulp and various treatment substances. The DN, DH, DHB, and DHP models are ideal for precise metering and pulse-free delivery, ensuring efficient handling of fluids with different densities, such as resins and dyes

Biogas:

- Recommended Pumps: Biogas Hopper Pump

- Overview: For biogas applications, our Progressive Cavity Pumps handle both low and high-viscosity fluids with fibres and adhesive substances. The DN, DH, DHST, and DV models are designed to perform reliably under variable temperatures and conditions typical of biogas plants, optimising the storage, feed, and discharge stages

Wine Production:

- Recommended Pumps: Hygienic Progressive Cavity Pump

- Overview: In winemaking, Nova Rotors’ pumps are designed for smooth transitions throughout the winemaking process. The DX, DH, DHE, DHP, DXO, DXC, RL, and R models are designed to handle the specific needs of wine production, ensuring efficient and gentle handling of sensitive liquids and maintaining high standards of hygiene and quality

Bakery & Dairy:

- Recommended Pumps: Flanged Progressive Cavity Pump

- Overview: Progressive Cavity Pumps are crucial in bakery and dairy industries for handling viscous and shear-sensitive materials like dough. The DM, DMX, and DX models are adept at transferring, depositing, and circulating dough and dairy products with precision, ensuring consistent product quality and efficient production

Chemical Processing:

- Recommended Pumps: Flanged Progressive Cavity Pump

- Overview: In chemical processing, our pumps are valued for their ability to handle corrosive, abrasive, and viscous substances. The DM and DMX models offer reliable performance in transferring and metering chemicals, providing high efficiency and minimal maintenance in demanding industrial settings

Testing and Quality Assurance

Nova Rotors doesn’t just build pumps – they ensure every unit is rigorously tested to meet your exact specifications:

- Detailed Performance Reports: Each pump undergoes extensive testing at Nova Rotors’ facility, with reports provided on pressure, capacity, NPSH, absorbed power, and torque. This ensures that every pump performs to the highest standards

- Independent Witness Testing: For the most demanding applications, Nova Rotors offers independent witness testing. This extra layer of verification guarantees that your pump will meet the strictest operational requirements

Why Tapflo UK Partnered with Nova Rotors

With our extensive experience and commitment to excellence, Tapflo UK has partnered with Nova Rotors to bring you superior solutions in Progressive Cavity pumping technology. Our collaboration with them ensures that you receive high-performance equipment tailored to your specific needs, whether for Wastewater Treatment, Biogas Production, or any other challenging application.

By combining Nova Rotors’ advanced pump technology with our dedicated support, we provide solutions that enhance your processes and ensure smooth, cost-effective operations. Trust in our partnership to deliver the expertise and equipment necessary for your success.

For more information on Progressive Cavity Pumps and how Nova Rotors’ range can assist with your specific needs, contact us today.