Peristaltic Pumps, also known as Tubing Pumps or Roller Pumps, stand out as versatile Positive Displacement Pumps in today’s market. Renowned for their self-priming capabilities up to 9.8 meters and outlet pressures reaching 15 Bar, these pumps find applications across various industries such as Food & Beverage, Pharmaceutical, Cosmetic, Wastewater Treatment and Chemical processing.

In this blog we highlight the key features of Peristaltic Pumps, factors to consider when selecting the correct pump for your application as well as the range we supply.

Operating Principle of Peristaltic Pumps

Peristaltic Pumps operate on the principle of either two shoes (for high-pressure applications) or rollers (for low-pressure applications) rotating on a wheel inside the pump. This rotation compresses an internal hose, propelling a specified quantity of fluid. The hose’s ability to return to its original shape ensures consistent fluid flow, resembling the natural peristalsis process. This design allows a variety of media to enter and pass through the pump, making it an efficient choice for various applications.

Key Features of Peristaltic Pumps

- Features a hose as the only component in contact with the fluid, minimising the risk of contamination

- Classified as Positive Displacement Pumps for accurate and consistent fluid transfer

- Suitable for low and high-pressure transfer, metering and dosing applications, making Peristaltic Pumps some of the most versatile pumps on the market today

- Self-priming up to 9.8m, reducing the need for external priming systems

- Capable of achieving high outlet pressures of up to 15 Bar, making these pumps well suited to industrial applications

- Suited to handling low and high viscous, pure, neutral, aggressive or abrasive liquids, as well as those containing gases or solids

- Sealless design, enhancing your pump’s performance and longevity

- Hose selection based on your application

- Shape-retaining hose design meaning it can retain consistent fluid quantity and flow

Factors to Consider when Purchasing a Peristaltic Pump

Pressure:

Tailoring the pump selection to your application’s pressure requirements is crucial. For pressures up to 4 Bar, the PTL Peristaltic Pump is recommended, while the PT Peristaltic Pump is better suited for applications exceeding 4 Bar.

Type of Hose:

The choice of hose is critical for optimal Peristaltic Pump performance. Tapflo UK offer a range of high-quality hoses, each catering to specific applications as follows:

- NR – Natural Rubber (white marking): most flexible, high abrasion resistance

- NR Food – Natural Rubber certificate CE 1935-2004 and FDA-Approved (black or white inside): appropriate for the food industry

- NBR – Nitrile Buna (yellow marking):appropriate for oils, greases and polymers

- NBR Food – Nitrile Buna certificate CE 1935-2004 and FDA-Approved (black or white inside): appropriate for the food industry

- EPDM – Ethylene Propylene Diene Monomer (red marking): high chemical resistance

- HYPALON/SYNTHETIC RUBBER – Chlorosulfonated Polyethylene (blue marking): high chemical resistance to fluids like sodium hypochlorite, chromic, nitric and sulfuric acids

- VITON/FKM (purple marking): high chemical resistance, especially to solvents, lubricants, petrol and fuels. Good temperature resistance

Clean in Place (CIP) Capability:

The CleanPRO is our CIP Peristaltic Pump, ideal for industries where contamination must be avoided. This pump facilitates efficient cleaning without dismantling equipment, ensuring a sterile environment.

Our Range of Peristaltic Pumps & Accessories

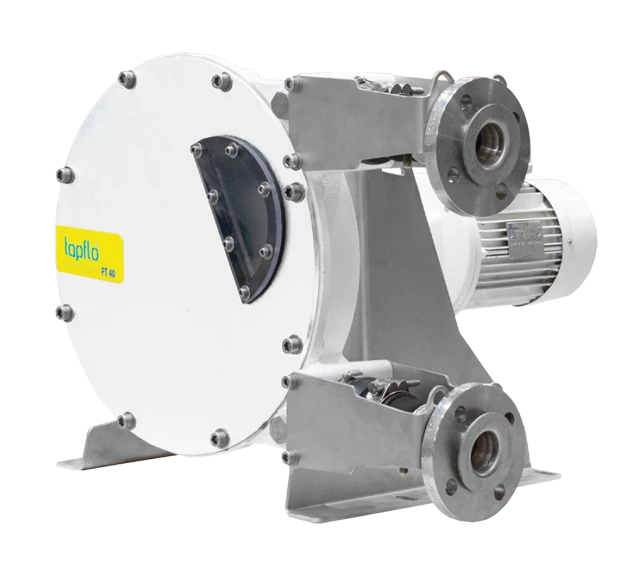

PT High-Pressure Peristaltic Pump:

- Shoe design

- Self-priming up to -0.9 Bar

- Viscosities up to 100,000 cPs

- Reversible operation

- 15 sizes available

- PXT is the ATEX-rated variant of this pump

PTL Low-Pressure Peristaltic Pump:

- Roller design

- Self-priming up to 0.6 Bar

- Viscosities up to 100,000 cPs

- 6 sizes available

- PXTL is the ATEX-rated variant of this pump

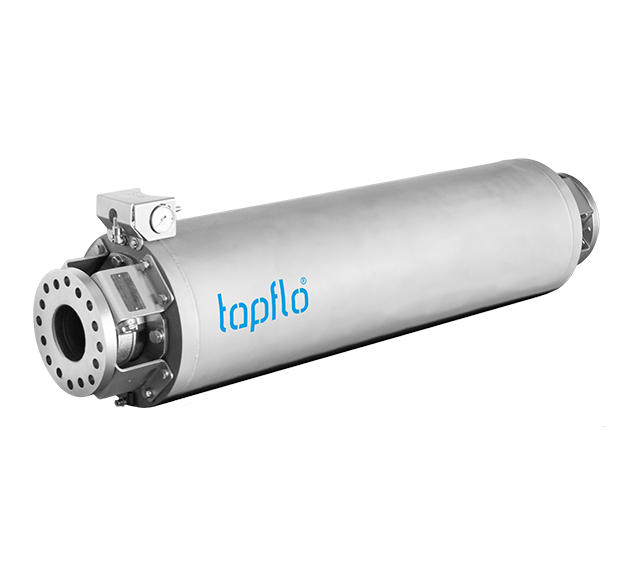

CleanPRO CIP Peristaltic Pump:

- FDA and EN1935 certified hoses

- Sealless design

- Sanitary clamp and thread connections

- CIP shoe design

- 2 sizes available

- ATEX-available

- Designed to reduce pulsation, vibrations and hammering in your pipe system

- Designed for Peristaltic Pumps, can be used for all pump types

- Complies with European PED Directive 2014/68/EU

- Can handle viscous fluids with particles up to 20% of the inner hose diameter

- ATEX-available

- Range includes Rubber, Suction and Delivery, Oil Resistant, Chemical, Sanitary and Food-Grade Hoses

- Supports effective operation of your Peristaltic Pump

- Certified and fully traceable

- Complies with European PED Directive 2014/68/EU

- ATEX-available

Learn more about our comprehensive range of Peristaltic Pumps in our dedicated YouTube video:

Navigating the world of Peristaltic Pumps requires careful consideration of factors such as pressure, hose type, CIP capability and applications. With Tapflo UK’s range of pumps and expert guidance, you can confidently select the right Peristaltic Pump tailored to your unique application needs. Explore our comprehensive guide for a deeper understanding of Tapflo UK’s Peristaltic Pumps and their applications.