If you’re in the market for a pump system that delivers consistency, versatility and precision, then a Positive Displacement Pump could be the ideal solution for you. In this comprehensive guide, we’ll explore everything you need to know about Positive Displacement Pumps, including their operating principle, various types as well as the benefits they offer.

What is a Positive Displacement Pump

At its core, a Positive Displacement Pump operates on a straightforward principle. It traps a fixed amount of fluid within its chamber, using sealed valves or seals, and then propels this fluid through to the discharge side. Regardless of changes in pressure, these pumps maintain a constant flow at a consistent speed.

Positive Displacement Pumps are commonly recognised as one of the most widely used process pump systems on the market, incorporating a variety of popular pump types.

Types of Positive Displacement Pumps

There are two primary categories of Positive Displacement Pumps: Reciprocating and Rotary.

- Reciprocating Positive Displacement Pumps: these pumps operate by performing repetitive alternating strokes, creating a vacuum within the pump chamber. This vacuum enables the fluid to be pushed through to the discharge side. Diaphragm Pumps, Flexible Impeller Pumps and Peristaltic Pumps are common examples.

- Rotary Positive Displacement Pumps: utilising a rotating gear system, Rotary Positive Displacement Pumps ensure a smooth and continuous flow to the discharge side. Four common types in this category include Internal Gear, External Gear, Vane and Rotary Lobe Pumps.

Let’s explore the common Positive Displacement Pump types and their categories:

- Diaphragm Pumps: Reciprocating

- Rotary Lobe Pumps: Rotary

- Screw Pumps: Rotary

- Flexible Impeller Pumps: Reciprocating

- Peristaltic Pumps: Reciprocating

- Gear Pumps: Rotary

- Vane Pumps: Rotary

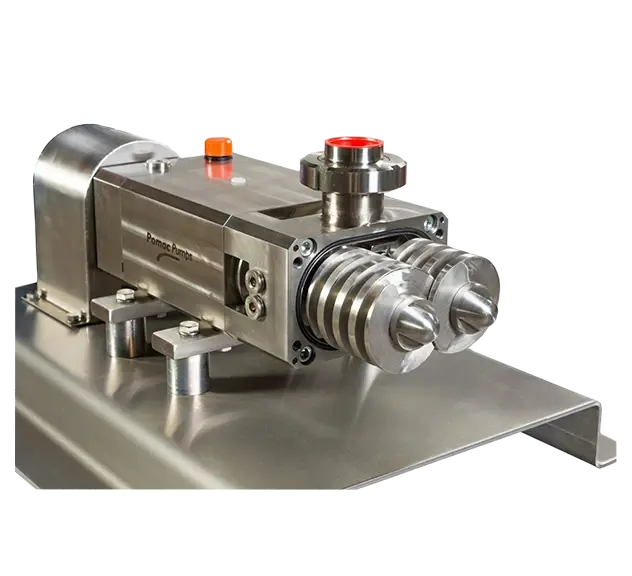

Sanitary Lobe Pump

Non-Positive Displacement Pump Types

While Positive Displacement Pumps shine in specific applications, they differ from Non-Positive Displacement Pumps, like Centrifugal Pumps, Multi-Stage Hydraulic Pumps and Magnetic Drive Pumps. Centrifugal Pumps, for example, rely on impellers to generate centrifugal force for fluid movement.

Looking for additional information on Centrifugal Pumps? This dedicated Guide to Centrifugal Pumps is your go-to resource.

Choosing Between Positive Displacement and Centrifugal Pumps

The choice between a Positive Displacement Pump and a Centrifugal Pump often hinges on the specific requirements of your application. Here’s a quick comparison:

Common Positive Displacement Pump Applications and Handled Fluids:

- High-viscosity fluids (e.g., cooking oils, mineral oils)

- High-pressure requirements

- Low flow rate requirements

Common Centrifugal Pump Applications and Handled Fluids:

- Low-viscosity fluids (e.g., water, juice)

- Tank-to-tank transfer applications

- High-flow applications

If you’re unsure about the pump type that best suits your requirements, reach out to our Sales Team for expert support and guidance.

Advantages of Rotary Positive Displacement Pumps

Rotary Positive Displacement Pumps, including Internal and External Gear, Lobe and Vane Pumps, offer a range of benefits such as:

- Accurate and pulseless flow at high differential pressures

- Capability to handle highly viscous fluids

- Effective at high differential pressures and varying flow rates

- Efficient suction lift applications

- Suitable for viscous fluids with our without solids

When it comes to handling various fluid characteristics, Rotary Positive Displacement Pumps exhibit different technical abilities:

E = Excellent, G = Good, A = Average, P = Poor

| Abrasives | Thin Liquids | Viscous | Solids | Dry Prime | Different Pressure |

| Internal Gear | G | G | E | P | A |

| External Gear | P | G | G | P | A |

| Lobe | G | A | E | E | A |

| Vane | P | E | A | P | G |

Positive Displacement Pump Range

Here at Tapflo UK, we proudly offer a diverse range of Positive Displacement Pumps, including Diaphragm, Lobe, Screw and Flexible Impeller Pumps, to name a few. Let’s take a closer look at a selection of our offerings:

Diaphragm Pumps:

Our Diaphragm Pumps operate using air pressure, featuring two diaphragms for efficient fluid transfer. The benefits include:

- Ability to run dry without damage

- Self-priming up to 5m

- Fewer components for enhanced reliability

- Air-operated, no electricity required

- Option for LEAP technology to save on air consumption

- ATEX-rated models available

Make the switch to Tapflo Diaphragm Pumps today! Need more information? Take a look at our article highlighting the advantages of using a Diaphragm Pump from Tapflo UK.

Lobe Pumps:

Designed for use in Sanitary applications, Lobe Pumps operate by using two rotating lobes. Key advantages include:

- Full EHEDG compliance for sanitary use

- ATEX-rated models

- CIP/SIP friendly

- Discharge pressure up to 15 Bar

- Suitable for high-temperature applications (up to 140°)

For additional information, check out our Guide to Sanitary Lobe Pumps.

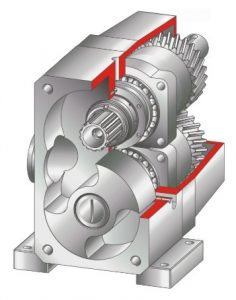

Twin Screw Pump:

The Twin Screw Pump combines the best of Lobe, Peristaltic, Centrifugal and Circumferential Piston Pumps. Their features include:

- Self-priming up to 8m

- Full EHEDG compliance for sanitary applications

- Ability to dry run briefly

- Pulsation-free pumping

- Discharge pressure up to 16 Bar

Flexible Impeller Pump:

These units push fluid forward by trapping it between vanes of the impeller. Some benefits include:

- Reversible operation

- Pulse-free pumping action

- Customisable with various executions and impeller materials

- Discharge pressure up to 4 Bar

- Suitable for handling temperatures up to 120°C

Discover the many advantages of using a Flexible Impeller Pump here.

Peristaltic Pump:

Peristaltic Pumps are easily maintained and create a pulsating flow using shoes or rollers on the hose wall. Advantages include:

- Self-priming up to 9.8m

- Minimal contact with pumped product (only the hose)

- Capable of limitless dry-running

- Available in low-pressure and high-pressure ranges

- Simple and robust design

Gear Pumps:

A Gear Pump, which is a Rotary Positive Displacement Pump, employs rotating cogs/gears for fluid transfer. Both internal ad external Gear Pumps fall under the Positive Displacement category and are supplied for industrial applications. Key benefits include:

- Accurate and pulseless flow

- Ability to handle viscous fluids

- Operates at high differential pressures

- Efficient suction lift

- Bi-directional operation

- ATEX-rated models available

To recap, Positive Displacement Pumps excel in industries requiring a steady and dependable flow and are ideal in applications characterised by high viscosity and low flow rates. Reciprocating and Rotary Pumps serve various purposes, while Centrifugal Pumps offer an alternative for specific applications. At Tapflo UK, we offer a wide range of Positive Displacement Pump systems that can be tailored to suit your unique flow needs.

If you’re unsure about which Positive Displacement Pump suits your application best, don’t hesitate to contact our team of experts for guidance and support.