A client of ours approached us looking for a Hygienic Pump solution for a current new site build for one of their customers who manufactures a health drink. The new site was commissioned at the end of March, with the enquiry coming to our team at the end of January, this was plenty of time to develop a solution and get it manufactured for our customer in time.

Application Details

The customer was looking for 2 pump options, the first would be used to feed IBCs with Reverse Osmosis (RO) Water. This pump would be in the warehouse and was required to achieve 80-100L/min at 6mWc. The second solution was required to feed the break tank with the product. Located in the Bulk Room, handling the product which is 1 cp (water-like) and needed to achieve 10L/min at 2mWc.

Pump Solution

As the final product is intended for use by humans, the manufacturing process must meet strict hygienic guidelines, this meant that all solutions offered by Tapflo UK would be FDA or EHEDG rated, with high-quality surface finishing for optimal hygiene and cleanability.

For the first pump that is feeding IBCs with RO Water, a CTH-AA-03 was selected. The pump is fitted with a hygienic motor shroud and impeller tripped to ø69mm to provide exact duty.

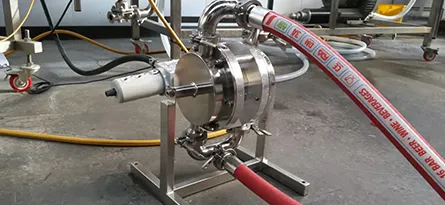

The second pump that is feeding the break tank with the product is a TC80 STT Sanitary LEAP Pump.

To ensure that the correct pump solutions were offered, our team had multiple conference calls with our customer and the end-user to discuss the factory build enabling decisions on optimal installation locations for the pumps to be made, as well as discussing minimising friction loss in pipework and a general overview of each pump technology.

Features & Benefits

The Tapflo CTH Pump was selected due to being a cost-efficient solution for the end-user whilst still adhering to hygienic standards. The pump also included a motor shroud to allow operators to continue with washdown procedures that are associated with hygienic installs.

The TC80 STT was offered for product dispensing, featuring Tapflo’s reliable Sanitary Diaphragm design paired with revolutionary LEAP technology. A Low Energy Pump was chosen due to the low operational flow and pressure requirements, as well as minimal air consumption required by the site.

LEAP can benefit a range of industries, discuss your application with our team to see if our low energy technology could benefit your application and your energy consumption costs!

General benefits of a Tapflo Sanitary Diaphragm Pump include:

- Pollution-free air valve – Sealing system is lubrication free, meaning no potential oil contamination!

- Maintenance-free ball check valve system

- Electropolished surface finish to Ra 0.8 as standard and 0.5 on request

- All pumps have a no-nut, clean face, one-piece bonded diaphragm, offering a longer life for the diaphragms and reduced risk of leakage. The clean face finish also means no room for growth of bacteria.

- 70% less working parts than other Diaphragm Pumps on the market for simpler maintenance

To find out more about Tapflo UK’s pump solutions, speak to one of our pump specialists today.