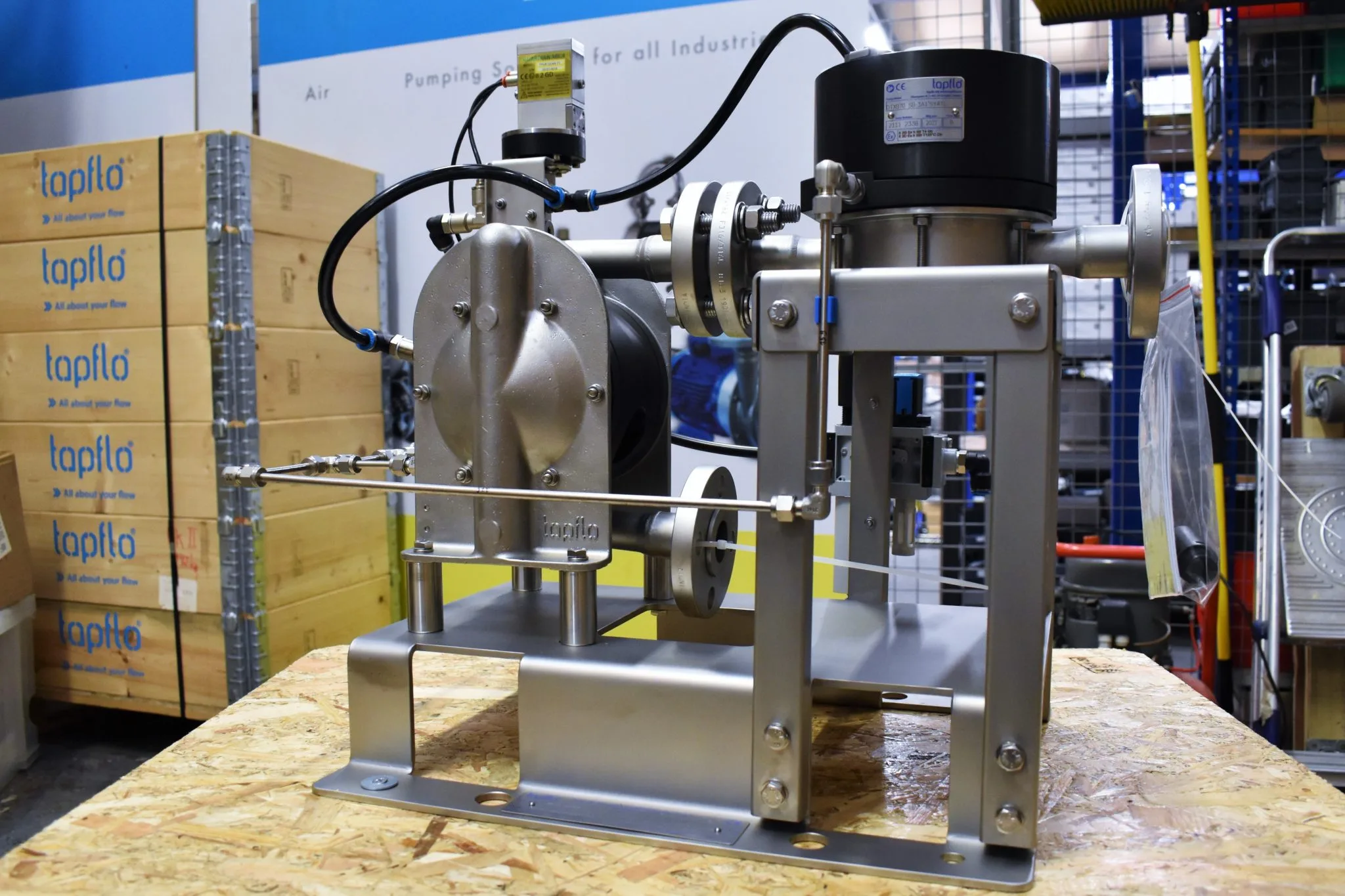

One of our long-standing clients in Chemical Manufacturing, Johnson Matthey, came to us requiring a solution to pump harsh chemicals in an ATEX environment. We supplied a bespoke ATEX Barrier Pump Skid System with our Barrier Diaphragm Pump and some added Tapflo pump accessories.

Application Details

- Fluid: Sodium Nitrate w/ Nitrate Salts (Corrosive & Abrasive Crystals)

- Duty: 20l/min @ 1.4Bar

- Temperature: 90°C

- Environment: ATEX Zone 1 Requirements

Because of the harsh chemicals being pumped, we opted for an ATEX Barrier Pump execution. This design has a backup diaphragm in the pump itself, ensuring high health & safety standards are kept as there’s no risk of leakage if the diaphragm ruptures.

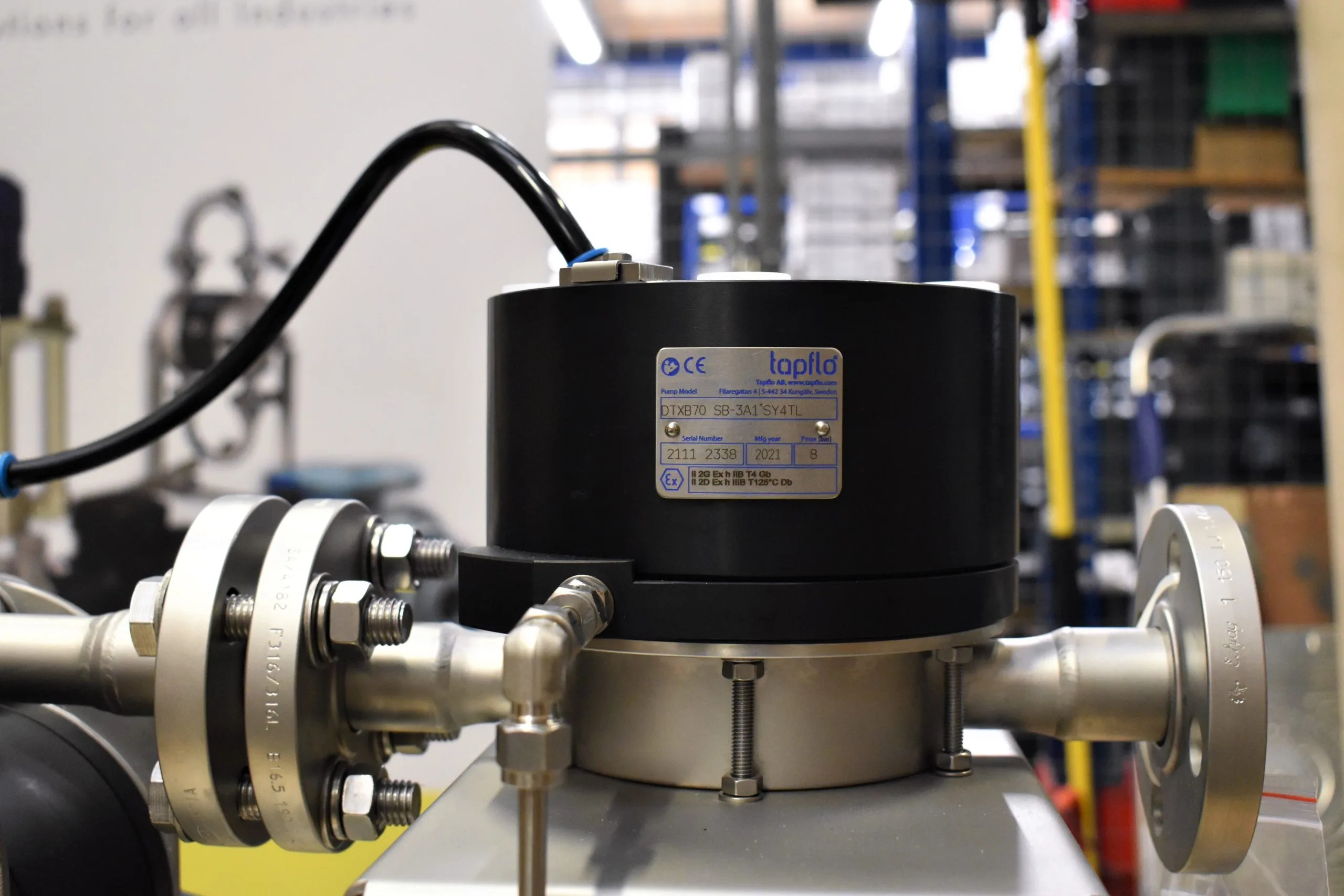

To complement this, we also offered a Pulsation Dampener with barrier execution, as this lowers pulsation of the pump considerably, and prevents water hammering & damage to the pipework.

One of our Guardian Systems was mounted to both the pump and dampener to monitor diaphragm condition and turn the pump off in a rupture event, preventing further damage. Only 1x Guardian system was installed to monitor both pump & dampener to fit within the client’s budget constraints.

An air treatment kit was also supplied, ensuring correct air quality was provided to both the pump and dampener (because Tapflo units utilise non-lubricated air valve systems), along with providing manual controllability to pump stroke speed via a needle valve, and an isolation valve to the air line.

The system was fitted onto an AISI304 sandblasted skid frame, ensuring the dampener is correctly supported onto the pump discharge flange (for optimal dampening effect) and also allowing easy transport around via FLT.

Equipment Supplied

- 1x TXB70 SBT-3A1″SY4TL – Barrier Pump

- 1x DTXB70 SB-3A1″SY4TL – Barrier Dampener

- 1x 6-100-003FX – Air Treatment Kit

- 1x PDFM-070 – Diaphragm Monitoring Kit

- 1x S2768 – Skid Frame Assembly for Pump + Dampener

The complete system was made as compact as possible (650 (L) x 420 (W) x 550mm (H).