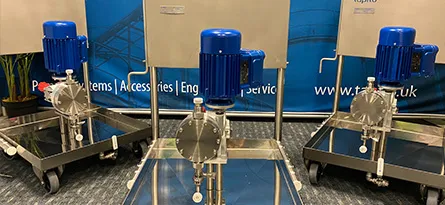

Tapflo UK were approached by a leading Pharmaceutical company to provide some ATEX Rated Hastelloy C Dosing Pumps on mobile trolleys. Our design team worked closely with the customer to provide a safe and simple solution based on specific requirements.

Application Details

One of our customers in the Pharmaceutical Industry needed 3 off safe, simple, accurate and mobile solutions for dosing a reagent (98-100% H2SO4 & Toluene at Ambient Temp) onto their process across a flow range of 23-138 l/hr with a max rated pressure of 10 Bar.

The customer specified that the only approved wetted materials to be used were Hastelloy C-276 & PTFE, and that the pump also needed to be suitable for a Nitrogen Injection Clean Through (2 Bar through suction side of the pump) and fitted with Tri-Clamp Connections on the suction & discharge. The pump sets also needed to be fitted to hygienic trollies and suitable for use in an ATEX Zone 1 environment.

Following conversations about the pump, our team were able to provide the client with a complete turnkey trolley package that included a drip tray, custom suction & discharge adaptors, and pump risers.

Solutions & Support

We worked with the customer on designing a bespoke trolley size that fitted their requirements, as per the initial design example pictured. Once approved by the customer, we then put all 3 packages into production and mounted all the equipment at our facility in Southampton before final shipping onto the customer so they had ready to use systems straight out of the box.

Equipment Supplied & Technical Details

3 x Motor Driven Mechanical Diaphragm Metering Pumps:

| Fluid | 98-100% H2SO4 & Toluene |

| Flow Range | 23 – 138 l/hr (10-60 Hz) |

| Strokes per Min (50 & 60 Hz) | 106 & 127 |

| Displacement per Stroke | ~18 ml |

| Accuracy | +/- 2% of rated flow, 0-100% |

| Adjustment | 0-100% Manual Stroke Length Adjustment while running or steady, 1 mm / turn & VSD Controlled |

| Max Suction Lift | 2-3 m from Dry, more with NRV fitted to suction line |

| Max Discharge Pressure | 10 Bar |

| Pump Head | Hastelloy C-276 |

| Diaphragm | PTFE |

| Seat | Hastelloy C-276 |

| Cage | Hastelloy C-276 |

| Valve | Hastelloy C-276 |

| Valve Seal | PTFE |

| Motor | 37 kW / 4 Pole / 230-400V / 3 Ph / 50 Hz / IP55 / Class F / ATEX II 2G Ex-d II B T4

Suitable for VSD control between 10-60 Hz @ Constant Torque |

| ATEX Classification | Motor: II 2G Ex-d IIB T4, and Pump: II 2 G T6 |

| Ambient Temp | -10ºC to +40ºC |

| Max Fluid Temp | 40ºC |

| Noise Level | <70 dB(A) |

| Certification | 1 Material Certs (All Hastelloy Parts), 2 Material Certs (All Elastomer Parts)

ATEX Certification (Covering Pump & Motor), EC Declaration of Conformity |

- 6 x 3/8″ BSP M x ½” Tri-Clamp Adaptors in Hastelloy C-276 (1 per pump port)

- 3 x 90º Swept Bend (Hastelloy C-276) c/w ½” Tri Clamps (C-276), PTFE Flange Gasket & Tri Clamp Band SS or Hastelloy (1 per pump suction)

- 12 x 100 mm x 20 mm Pump Spacers w/ M8 Female Threads, AISI 303

- 3 x Customised Tapflo Hygienic Trolley Model HM0X with Rounded Handle Bars

Fitted with above equipment

- 4 x Conductive Wheels, Swivel & Rear Locking w/ Earthing

- Drain Valve at Front

- Ra <1.6 Surface Finish

- Industrial Mounting Brackets for Pump to provide 100 mm Clearance from Base

Materials of Construction:

- Drip Tray: Stainless Steel AISI 304 (Inside Surface Electro-Polished, Outside Sandblasted)

- Handles: Stainless Steel AISI 304 (Ground)

- Support Plate between Handles: Stainless Steel AISI 304 (Sandblasted both sides)

- Wheel Supports: Stainless Steel AISI 304

- Drain Valve: Stainless Steel AISI 316

- Misc. Supports & Plates: Stainless Steel AISI 304 (Sandblasted both sides)

- Maximum Dimensions ( L x W x H ): 800 x 860 x 980 mm

Our Director, Luke Barnes, worked closely with our customer on this project and details some of the key specs of the system in the video below: