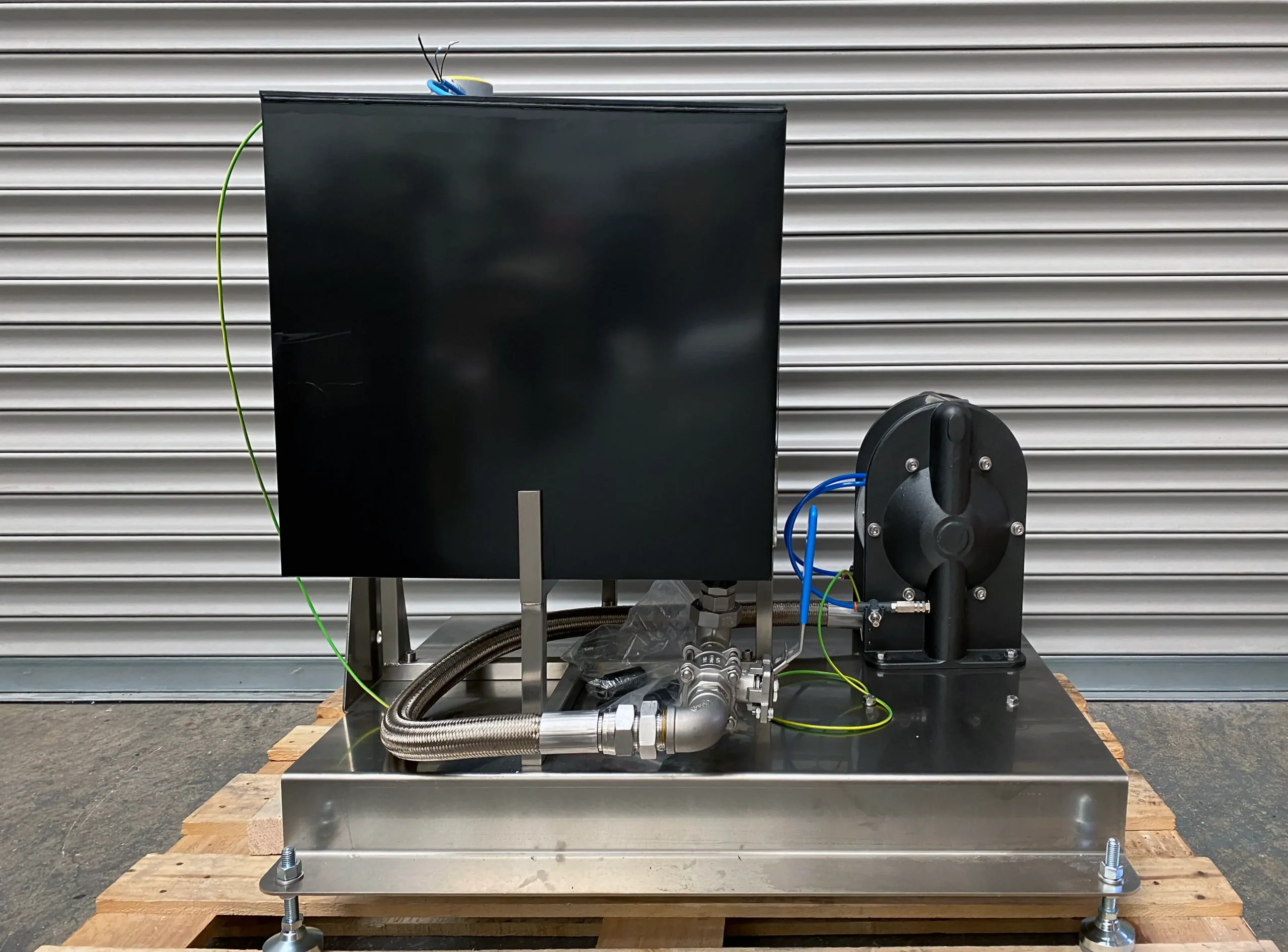

We designed 2 x Automated Powder Pumping Systems to allow dust to be captured & pumped back into dipping tanks in partnership with Exeon.

The Application

A manufacturer of Valves & Fittings in the UK had previously purchased & successfully used some of our TXP Powder Transfer AODDs for filling their Rilsan Powder Coating Dipping Tanks. During the dipping process, Rilsan dust is generated from the dipping tanks. As a result, the end user tasked Exeon with creating and supplying some ATEX Rated Dust Extraction and Recycling Systems whereby the dust could be captured & pumped back into the dipping tanks to reduce their operational and wastage costs. Tapflo UK, in partnership with Exeon, designed 2 x Automated Powder Pumping Systems.

- Industry: Powder Coating

- Location: Peterborough

- Order Placed: 10/05/2022

- Order Dispatched: 16/09/2022

- Medium: Rilsan Thermoplastic Synthetic Coating Powder

The Solution

The systems utilise radar-based level sensors to measure the level inside a small collection vessel connected to the suction of one of our TXP120 Powder Pumps. A control unit reads the level of the tank and controls the pump through internal VFC (volt-free contact) relays to supply or remove power to a solenoid valve on the pump’s air supply.

As the tank fills up the controller recognises the level; when the level reaches the high level programmed into the controller, it turns the pump on. The pump will then empty the tank until it reaches the low level programmed into the controller, at which point the pump is turned off and the tank starts filling up.

Why we Selected this Technology

Tapflo TXP Power Transfer AODDs were used as they are specifically designed for use in transferring dry, flowable powders with a density range of 80 – 720 kg/m³.

These pumps are incredibly compact, ATEX Rated as standard, and feature a variable onboard powder fluidisation system which prevents powder backup problems on start-up and enables fine-tuning of the fluidisation. Furthermore, through the use of our Air Filter Regulator and Needle Valve on the air supply to the pump, operators are able to change the flow and pressure from the pump to suit application requirements.

Radar sensors were employed on these systems as they provide a high level of accuracy (+/- 2 mm) with easily adjustable set points over a 15 m range. Furthermore, Radar technology is a non-contact level measurement technology which is ideally suited to measuring bulk solids such as powders, which are difficult to measure the level of with traditional contact style measurement technology.

The controllers used provide a high level of functionality with a real-time level indication in the tanks on board the systems. Colour Changing Display Status indication also provides a quick and customisable error or fault indication to operators, should levels within the tank deviate from their “healthy” set levels.

Both Controllers and Sensors are also Bluetooth enabled so Operations and Engineers can quick log onto a free app to monitor levels as well as conduct system health checks, diagnostics and troubleshooting.

System Overview

- TXP120 XTTS Powder Pump

- Adjustable Top Hat Style Base Plate with Anti-Vibration Mounts

- Custom 60 litre Conical Tank in Conductive HDPE with Painted Mild Steel Stand

- Radar Level Sensor

- Radar Control & Display Unit

- Custom mounting bracket for radar sensor.

- Custom Convoluted PTFE suction & discharge hose assemblies

- Valves & Fittings for connection of system components on the skid as well as to process